DF series fully automatic self-cleaning filter

DF series fully automatic self-cleaning filter

The DF series fully automatic self-cleaning filter (scraper-type self-cleaning filter) automatically removes

particle impurities on the surface of the filter screen through efficient mechanical scraping. Through time/pressure

differential control, it automatically discharges high-concentration impurities in the machine. It can be filtered

continuously on-line by single machine without generating filter consumables and does not require frequent manual

cleaning. It is suitable for general and highly viscous liquid filtration.

When traditional manual filters filter sticky materials and high-deficiency materials, they are frequently blocked, and

customers are forced to choose large filters or perform frequent backwashing. The investment is large, the work is heavy,

and the material waste is serious. DF filters can easily solve this type of problem, always keep the filter element clean

regularly, the concentration of impurities discharged from waste liquid is high, and the waste of materials is small. With

its significant technical advantages and low operating costs, DF filters are gradually replacing traditional manual filters

such as vibrating screens, bag-type, basket filters and some recoil-type self-cleaning filters in many fields.

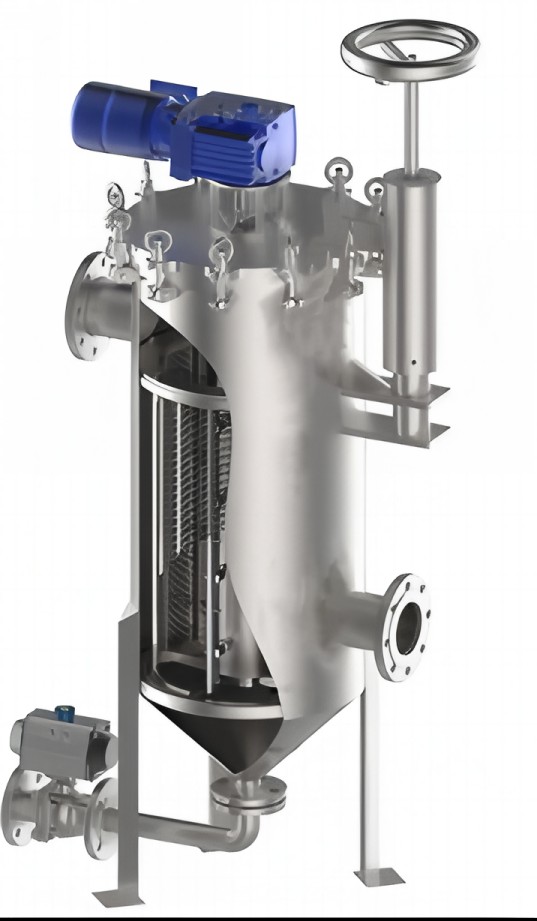

DF series filters can be divided into three sub-models according to the application conditions:

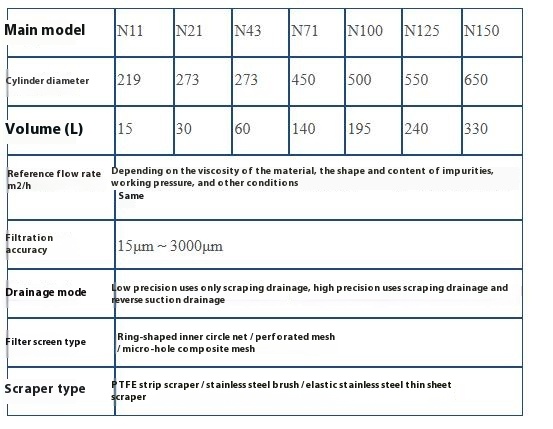

DF-N type: inner scraping type, that is, the scraper blade (stainless steel or tetrafluoro scraper) is driven by a speed reduction

motor to rotate and scrape away impurities on the inner surface of the filter;

DF-W type: external scraping type, that is, the strip scraper blade (scraper or scraper) is driven by the reduction motor to rotate

and scrape away impurities on the outer surface of the filter;

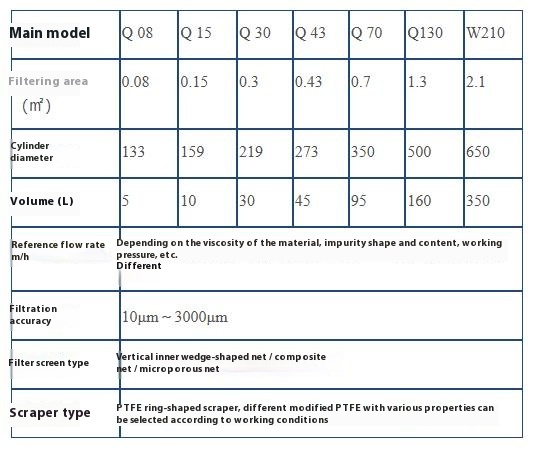

DF-Q type: ring scraping type, that is, cylinder-driven ring scraping discs scrape the inner surface of the filter up and down;

Series fully automatic self-cleaning filter How it works

DF-N/W series self-cleaning operation mode:

The scraper driven by the speed reduction motor rotates to scrape off impurities on the surface of the filter. The impurities

leave the filter surface and fall into the impurities collection chamber at the bottom of the filter as the liquid descends. The

sewage valve opens according to the set procedure to discharge the impurities; the reverse suction component and scraper

component are used for high-precision to clean the impurities adsorbed on the surface of the filter element.

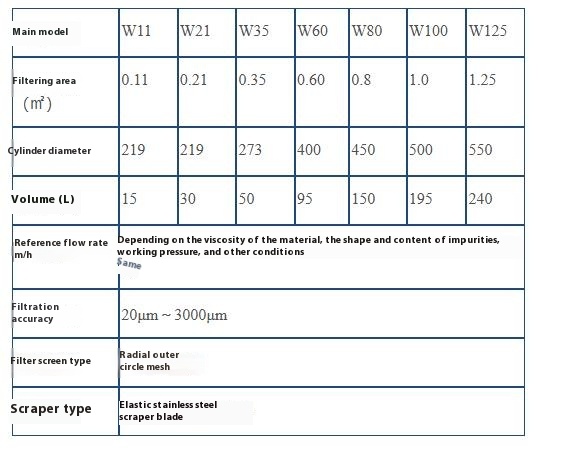

DF-W Series (Scrape Type)fully automatic self-cleaning filter

DF-Q series self-cleaning operation mode:

The cylinder drives the circular ring scraper plate to reciprocate and clean the filter. When the scraper plate moves downward,

impurities are pushed to the bottom of the filter, and the impurities are deposited in the collection chamber. When the scraper

moves upward, the filter screen is cleaned reciprocate. After the cleaning cycle is over, the sewage valve will automatically open

according to the settings to discharge the high-concentration impurities liquid.

DF-N series (scrape type)fully automatic self-cleaning filter

Series fully automatic self-cleaning filter Application Industry

Typical applicable industries: water treatment, papermaking, petrochemical, biopharmaceuticals, fine chemicals, food and beverages, etc.

Suitable liquid types: water, polymer, fermentation broth, vitamins, penicillin, protein, citric acid, sorbitol, steroids, ethanol, adhesives,

pigments, paints, inks, coatings, silicone solutions, rubber, juice, chitosan, agarose (gels), chocolate, cosmetics, lubricants, waxes, cooking

oils, high temperature oils, mixed oils, hydrocarbon oils, kerosene, diesel, coolant, etc.

Main filtration functions: filtering out large particles, fixed value screening, purifying fluids, collecting required solid particles, protecting key equipment, etc.

DF-Q Series (ring scraper type) fully automatic self-cleaning filter