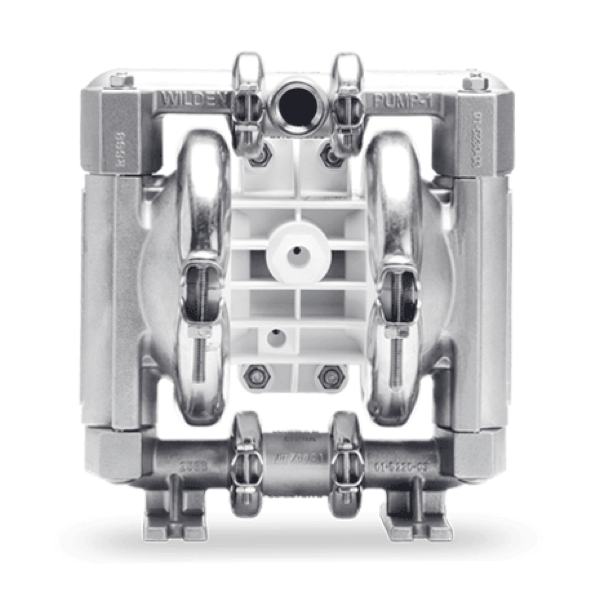

WILDEN 1.5-inch TZ4 series pneumatic diaphragm pump aluminum alloy marine chemical sewage pump pneumatic pump

WILDEN 1.5-inch TZ4 series pneumatic diaphragm pump aluminum alloy marine chemical sewage pump pneumatic pump

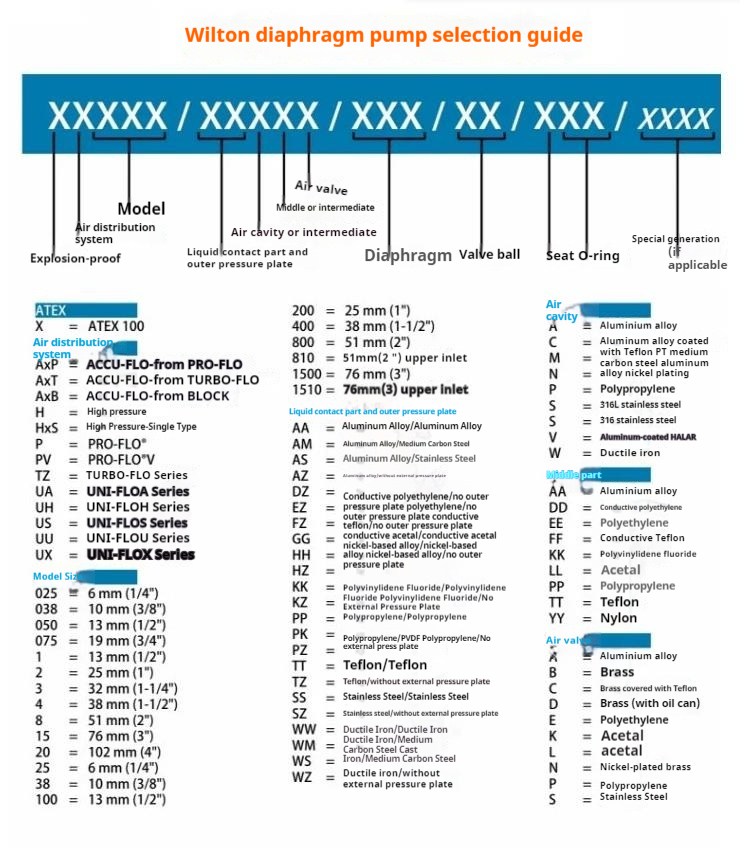

There are many models of Wilden diaphragm pumps, mainly including the following categories:

P series: including P025, P1, P2, P4, P8, P15 and other models. The maximum working pressure of these pumps is 8.6Bar, and the shell

material includes aluminum alloy, stainless steel, cast iron, and the diaphragm material is Neoprene, BN Dingling rubber, PTFE Teflon, Wil-Flex rubber

T series: including T1, T2, T4, T8, T15 and other models. The maximum working pressure of these metal pumps is also 8.6Bar, and the

shell is made of aluminum alloy, stainless steel, cast iron

Pro-Flo Series: Includes the Pro-Flo R® Series and the Pro-Flo SHIFT Series. The Pro-Flo R series is known for its excellent design and

reliability, while the Pro-Flo SHIFT series saves up to 60% of energy and increases flow by 34% through advanced air valve design

Special Pumps: Wilton also offers dedicated pumps that are specially designed to improve productivity, efficiency and safety in the segment

EXP Metal Pump: Such as 3" EXP Metal Pump, with large flow and a variety of material options, is suitable for heavy-duty pump solutions,

and its long-life diaphragm can last four times the service life of traditional diaphragms under normal operating conditions

Non-metallic pump: including PD02P-APS-PTA, PD02P-APS-PTT and other models, suitable for different sizes and needs

The pump body materials include: aluminum alloy, cast iron, stainless steel, Hastelloy, polypropylene, polyvinylidene fluoride, polytetrafluoroethylene

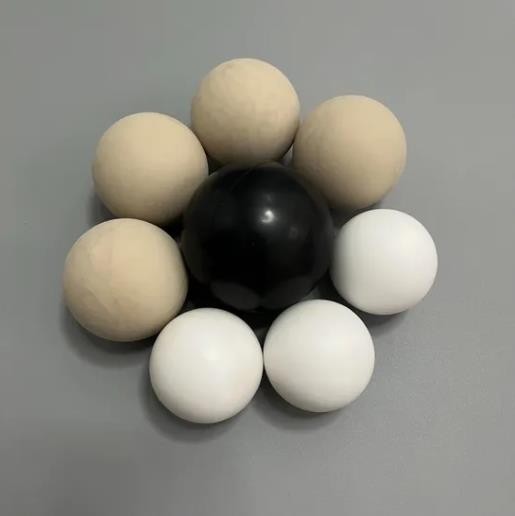

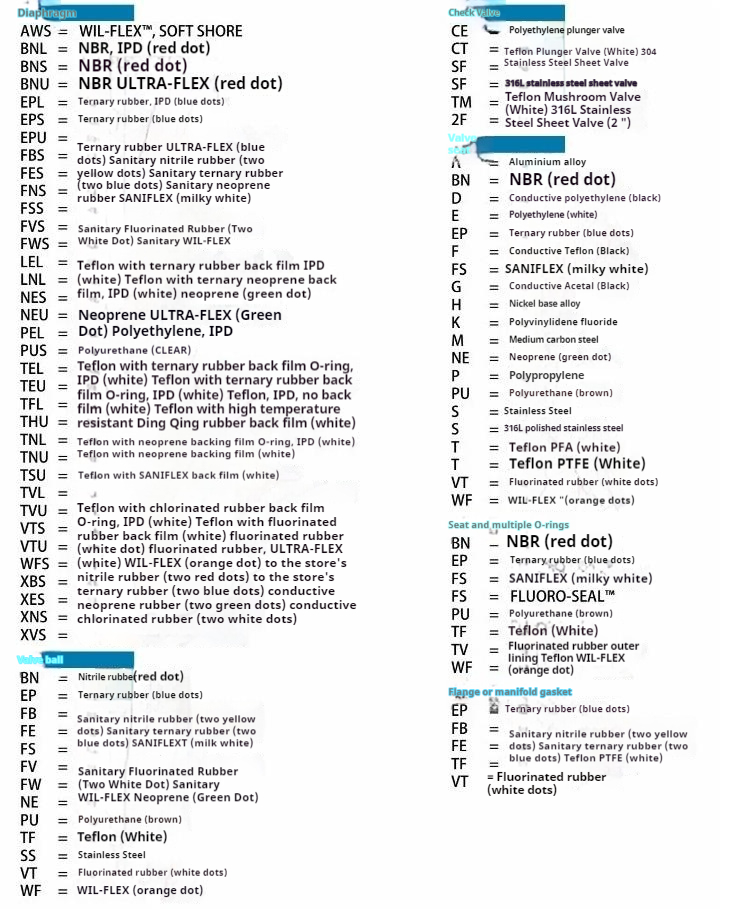

Diaphragms include: neoprene: a common purpose diaphragm suitable for non-aggressive liquid pumping fields, such as sewage treatment, tap water

or seawater, with good flexibility, economical and durable.

Dingjing Rubber: used to transport petroleum and oily liquids, such as leaded gasoline, diesel, hydraulic oil, kerosene engine oil, etc.

Fluorinated rubber: high temperature fluid pumping, high temperature resistance of 176 degrees, can also transport some aggressive liquids

Triple rubber: low temperature pumping, low minus 51 degrees, can also be used as a liquid with dilute acid or low corrosion

WIL-FLEX rubber: suitable for acidic or alkaline corrosive properties, such as hydroxide, sulfuric acid or hydrochloric acid, etc., it is comparable to neoprene

in terms of cost performance. This material has good wear resistance and durability.

Teflon Diaphragm: Pumping highly corrosive fluids such as sulfuric acid, fragrance, chlorinated hydrocarbons, ketones and acetates

Caliber: 1/4” 1/2” 1” 11/2” 2” 3” 4”

Traffic: 18LPM-1174LPM

Self-priming height: 7 meters

Intake pressure: 8.6BAR

General advantages of pneumatic diaphragm pump

No electric sparks, can run empty, can start work by self-priming, no complex control required, simple operation, self-priming height can reach 6M

The shell and diaphragm of the pump body can be used to transport strong acids, strong alkalis, and strong organic solvent liquid media with different characteristics.

No moving seal, no contamination of materials, low shear force, and does not easily damage the material structure

Can be submersible, movable, easy to carry, can be used as a mobile pump

No rotating parts (or bearings), no mechanical shaft seal, no connectors, low maintenance costs

The delivery speed can be changed by changing the gas volume

The conveying height can be changed by changing the pressure

Can convey high-thick and high-viscosity liquid media

You can switch the outlet at any time without any fear of blockage

Automatic pressure balance (no pressure relief valve required)