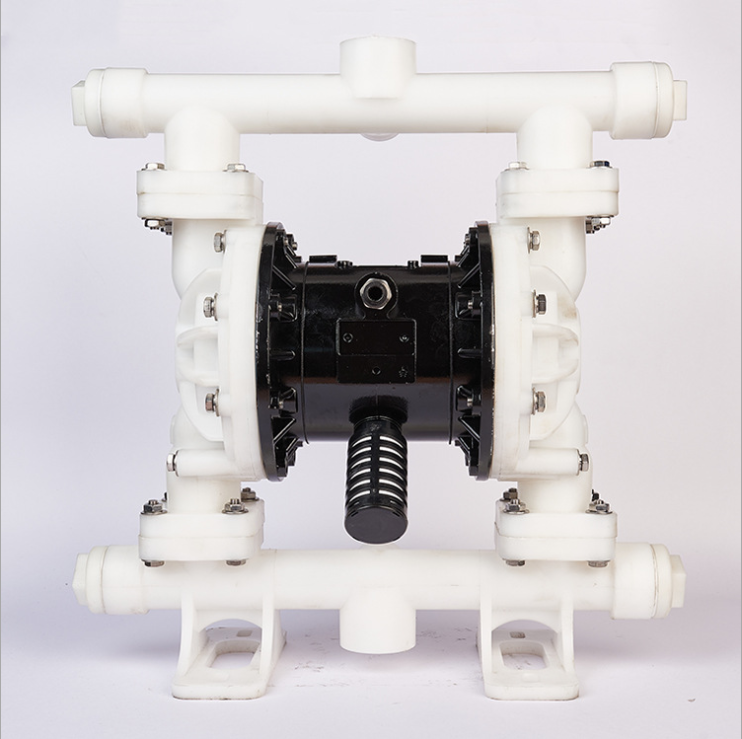

QBY3-20 QBY3-25 PP engineering plastic pneumatic diaphragm pump

QBY3-20 QBY3-25 PP engineering plastic pneumatic diaphragm pump can not only pump flowing liquids, but also transport some media that are not easy to flow. It has many advantages of self-priming pumps, submersible pumps, shielded pumps, mud pumps and impurity pumps. QBY engineering plastic pneumatic diaphragm pump is a new type of conveying machinery, using compressed air as the power source. It can completely pump out various corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids.

QBY3-20 QBY3-25 PP engineering plastic pneumatic diaphragm pump Technical parameters

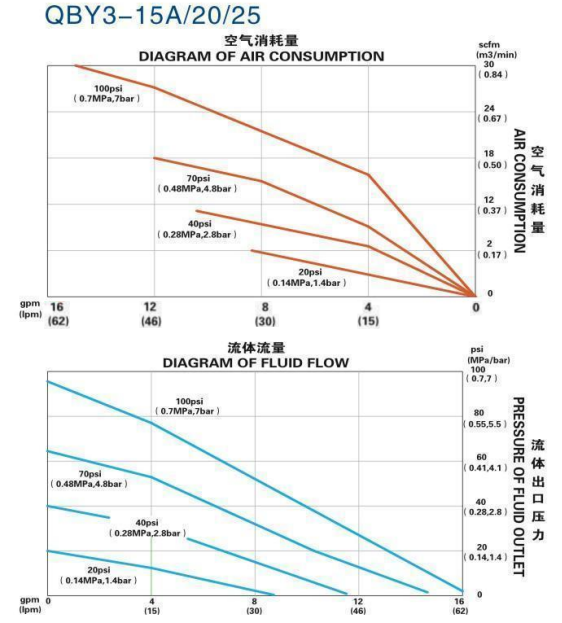

Flow rate: 0-30m3/h;

Lift: 0-50m;

Diameter: 10-100mm;

Temperature: -15-+120℃;

Pressure: 0.1-0.7MPa;

Self-priming height: 5-7m.

QBY3-20 QBY3-25 PP engineering plastic pneumatic diaphragm pump Scope of use

1. Pump peanut butter, pickles, mashed potatoes, sausages, jam apple pulp, chocolate, etc.

2. Pump paint, gum, pigment.

3. Adhesives and glues, all types can be pumped.

4. Various tiles, porcelain, bricks and pottery glaze slurries.

5. After the oil well is drilled, use the pump to suck sediment and grout.

6. Pump various emulsions and fillers. .

7. Pump various sewage.

8. Use the pump to clean the tanker and barge to suck the sewage in the warehouse.

9. Hops and baking powder slurry, syrup, molasses.

10. Pump the accumulated water in mines, tunnels, ore dressing, slag. Pump cement grout and mortar.

11. Various rubber slurries.

12. Various abrasives, corrosives, petroleum and mud, cleaning grease and general containers.

13. Various highly toxic, flammable, and volatile liquids.

14. Various strong acids, strong alkalis, and highly corrosive liquids.

15. Various high-temperature liquids can withstand up to 150°C.

16. As a pre-stage pressure delivery device for various solid-liquid separation equipment.

QBY3-20 QBY3-25 PP engineering plastic pneumatic diaphragm pump Working Principle

Working Principle of QBY Engineering Plastic Pneumatic Diaphragm Pump

In the two symmetrical working chambers of QBY Engineering Plastic Pneumatic Diaphragm Pump, there is an

elastic diaphragm 6, and the connecting rod connects the two diaphragms into one. After the compressed air

enters the air distribution valve 3 from the air inlet connector 1 of the pump, it pushes the diaphragms in the

two working chambers, driving the two diaphragms connected by the connecting rod to move synchronously.

At the same time, the gas in the other working chamber is discharged from the back of the diaphragm. Once

the end of the stroke is reached. The air distribution mechanism automatically introduces compressed air into

the other working chamber, pushing the diaphragm to move in the opposite direction, thus forming a synchronous

reciprocating motion of the two diaphragms. Two one-way ball valves 4 are set in each working chamber. The

reciprocating motion of the diaphragm causes the change of the volume of the working chamber, forcing the

two one-way ball valves to open and close alternately, thereby continuously sucking and discharging the liquid.

Troubleshooting of QBY engineering plastic pneumatic diaphragm pump:

1. Before disassembling the pneumatic diaphragm pump, mark the air chambers and liquid chambers on the left and right sides to assist in subsequent reassembly.

2. Use a wrench to loosen the small clamp connecting the outlet pipe and the liquid chamber. Remove the outlet pipe and see the valve ball and valve seat. Take out the ball and seat and check that other spare parts of the pump are worn, chemical corrosion, cracks, etc.

3. Use a wrench to loosen the small clamp connecting the inlet pipe and the liquid chamber. Remove the outlet pipe and see the valve ball and valve seat. Take out the ball and seat and check that other spare parts of the pump are worn, chemical corrosion, cracks, etc.

4. Use a wrench to separate the intermediate of the liquid chamber and the pump. Remove the liquid chamber and see the diaphragm and diaphragm clamp.

5. Use a tool or wrench to secure the left and right edges of the outer diaphragm ply to separate the diaphragm device from the intermediate. Then rotate clockwise to release the diaphragm device. After removing the outer diaphragm, remove the shaft from the intermediate.

6. Use clamps (padded wooden boards) to separate the shaft from the diaphragm device and check whether the shaft, clamp, and diaphragm are damaged and corroded.

7. Installation from step 6 to step 1

QBY engineering plastic pneumatic diaphragm pump has action, but the flow rate is small or there is no liquid flow out at all:

1. Check the air cavitation phenomenon of the pump and reduce the speed of the pump to allow the liquid to enter the liquid chamber.

2. Check if the valve ball is stuck. If the operating liquid is incompatible with the pump's elastomer, the elastomer will expand. Please replace the elastic body of the appropriate material.

3. Check whether the connector at the pump inlet is completely locked, especially the clamps near the valve ball at the inlet end need to be locked.

The air valve of the pump is frozen:

Check whether the water content of compressed air is too high and install air drying equipment

Air bubbles are generated at the outlet of the pump:

Check whether the diaphragm is broken and check whether the clamp is locked, especially the inlet tube clamp.

The product flows out of the air discharge port:

Check whether the diaphragm is broken, check whether the diaphragm and inner and outer splints are clamped on the shaft

The valve rattles: Increase the outlet or inlet head.

Pump Disassembly and Reassembly Guide:

Warning: Before repairing the pneumatic diaphragm pump, the air source pipe must be removed from the pneumatic diaphragm pump and the air pressure in the pneumatic diaphragm pump must be discharged. Remove all the lines connecting the inlet and outlet of the pneumatic diaphragm pump and discharge the fluid inside the pump into the appropriate container. Wear protective caps, glasses, gloves

QBY engineering plastic pneumatic diaphragm pump does not operate or is very slow to operate:

1. Check whether the filter mesh or air filter device at the air inlet is impurities.

2. Check whether the air valve is stuck and clean the air valve with cleaning liquid.

3. Check whether the air valve is worn and replace new parts if necessary.

4. Check the condition of the sealing parts of the center body. If it is severely worn, the sealing effect will not be achieved, and the air will be discharged from the air outlet. Due to its special construction, please only use the GLYD circle.

5. Check whether the piston in the air valve is active properly.

6. Check the type of lubricant. If the added lubricant oil is higher than the viscosity of the recommended oil, the piston may be stuck or function abnormally. It is recommended to use light and thin and anti-freeze lubricating oil. (ISO grade 15/5WT freezing oil)