No clogging, no damage, high efficiency, energy saving, hydraulic advantages, spiral centrifugal impeller

In recent years, with the development of human society, the impurities contained in discharged sewage have increasingly changed, and sewage pumping work is facing new and more serious threats. Long fiber objects, wet wipes, plastics, disposable products, fats, oils and oils (FOG) and even underwear worn by humans, as well as fish products, animal carcasses, plant branches and leaves and other types of garbage enter the pumping station. Large pieces will form in the pumping station and stick to the impeller of the water pump, causing the sewage pump to become clogged, causing the pumping station to be unable to drain water normally, causing serious water pollution to the environment.

Equipped with a spiral centrifugal impeller assembly, the spiral centrifugal submersible pump can transport general sewage and wastewater containing a large amount of solid particles and fibrous substances, whether it is an open single-channel spiral centrifugal impeller or an open forward-swept spiral centrifugal impeller. The non-blocking characteristics of the large channel ensure that the pumping of viscous water quality and various types of water quality that require gentle transportation can be easily handled.

The hydraulic advantages of spiral centrifugal pumps combined with the unique FreeFlow technology advantages

FreeFlow technology is based on two innovations: the dolphin beak and the self-cleaning end cap

The spiral centrifugal submersible pump has excellent non-clogging technology, dolphin beak and self-cleaning end cover. The revolutionary FreeFlow technology will completely improve the hydraulic characteristics and stability of the spiral centrifugal submersible pump, even if the pumping function is required to be increased due to changes in the medium. The more stringent it is, the spiral centrifugal submersible pump can also pump media containing large blocks and long fibers as well as media with high viscosity and high solid content.

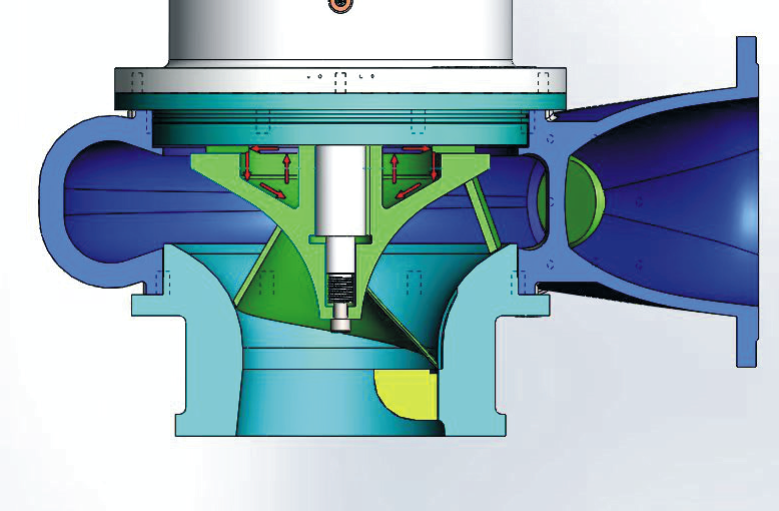

Self-cleaning end cap

The self-cleaning end cover is located behind the impeller to reduce the problem of impurity accumulation behind the impeller and at the mechanical seal. The specially designed geometry of the self-cleaning end cover can form a circulating liquid flow between the impeller and the back cover to achieve a cleaning effect and avoid The accumulation of solid particles behind the impeller reduces wear on the mechanical seal.

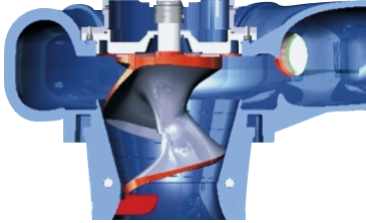

Dolphin beak (red part in the picture)

The dolphin beak is installed at the suction inlet of the water pump. It can effectively retain the solid and long fiber substances in the medium entering the suction inlet, and change the flow direction to flow into the center of the impeller, reducing the possibility of clogging and preventing the impeller tip. Hooking fibers to cause clogging also prevents fibers from wrapping around the impeller and causing damage to the impeller tip, solving the problem of fibers clogging the pump in traditional non-clogging pumps. Therefore, the installation of the dolphin beak does not change the inherent excellent hydraulic characteristics of the spiral centrifugal impeller itself, but precisely solves the problem of solid particles and fibers clogging the pump in traditional non-clogging pumps.

Post time:2024-11-19