Spiral non-clogging submersible centrifugal pump advantage

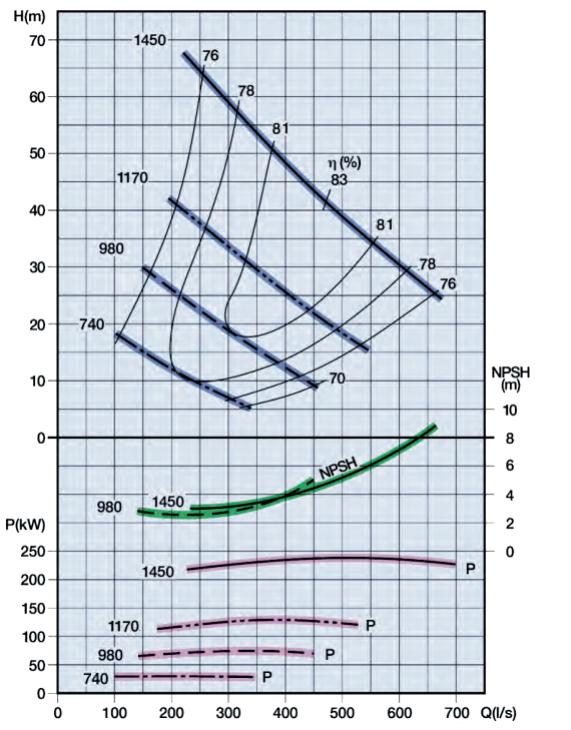

High efficiency, low energy consumption, dead weight, smooth operation, no overload in all working conditions

→High efficiency, low cost

A steep performance curve and a stable operating point

1. Lower cavitation content and higher self-priming ability

- Flat power curve, no overload area in all working conditions - Low transfer structure, dead weight, smooth operation, 30%~50% heavier than similar pumps

Energy loss and impeller wear are caused by turbulent water flow, sharp changes in flow direction and local high flow rates. Due to the structure of the Heinet spiral centrifugal impeller, energy is transmitted to the medium step by step, and the water conservancy flow channel is very gentle, runs smoothly and has a large diameter. , reducing the recirculation of liquid within the pump. Therefore, the pump has high efficiency, small motor power and low energy consumption, which can save energy, reduce pump wear and reduce maintenance costs. Energy saving comparison

Compared with single-channel impeller, it saves 5%~20% energy.

Compared with vortex pump, it saves 50%~60% energy.

Efficiency comparison

5%~10% higher than ordinary impurity pump

10%~20% higher than cyclone pump

Post time:2024-11-19