LW vertical non-clogging sewage pump

LW vertical non-blocking sewage pump is suitable for the discharge of severely polluted wastewater from factories and businesses, sewage discharge stations in main residential areas, water distribution systems of urban sewage treatment plants, drainage stations of civil air defense systems, water supply equipment of water plants, and sewage of hospitals and hotels. It is used in industries such as emissions, municipal engineering construction sites, mining supporting machinery, rural biogas pools, farmland irrigation and other industries to convey granular sewage and dirt. It can also be used for clean water and weakly corrosive media. Commonly used models are: LW50-20-7-0.75, LW25-8-22-1.1, LW50-10-10-0.75, LW50-20-15-1.5, LW50-15-25-2.2, LW50-18-30- 3. LW50-40-15-4, LW50-20-40-7.5, LW65-37-13-3, LW80-40-7-2.2, LW80-43-13-3, LW80-40-15-4, LW80-65-25-7.5, LW100-80-10-4, LW100-100-15-7.5, LW100-80-20-7.5, LW100-100-30-15, LW100-100-35-18.5, LW150- 145-9-7.5, LW150-180-15-15 and other series

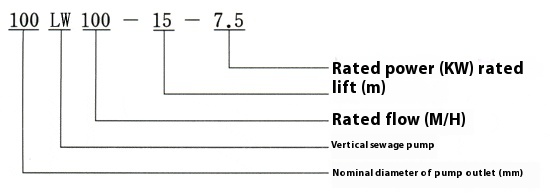

Model significance of LW vertical non-clogging sewage pump

Overview of LW vertical non-clogging sewage pump

LW vertical non-clogging sewage pump is developed through the introduction of foreign technology through absorption and transformation. All performance indicators have reached the standard level of similar products. Due to the use of a unique single (double) channel impeller, it has strong sewage discharge capacity and can effectively pass through 5 times the fiber diameter of the pump diameter and solid particles with a diameter of 50% of the pump diameter. The dynamic seal uses two sets of cemented carbide mechanical seals made of special materials. Device, made of cast iron and stainless steel.

LW vertical non-clogging sewage pump product features:

1. The mechanical seal adopts a new type of grinding pair and operates in the oil chamber for a long time;

2. The overall structure is compact, small in size, low in noise, significant in energy saving, easy to maintain, and convenient for users to replace.

3. The double-blade impeller structure is adopted, which greatly improves the passing capacity of dirt.

4. The automatic control cabinet can automatically control the overshoot and stop of the pump according to the required liquefaction changes, without the need for special supervision, and is extremely convenient to use;

5. The installation method can be equipped according to the user's needs, which brings great convenience to installation and maintenance. People do not have to enter the sewage pit for this purpose;

6. It can be used within the design range without overloading the motor;

7. The pump is equipped with an outdoor motor, so there is no need to build a pump room and can be directly installed and used outdoors to save money;

Conditions for use of LW vertical non-clogging sewage pump:

1. LW vertical sewage pump series products are suitable when the rated voltage is 380V and the power frequency is 50Hz.

2. The medium temperature does not exceed 40 degrees Celsius, the medium density is ≤1150kg/m3, and the PH value is within the range of 5-9;

3. The altitude does not exceed 1,000 meters;

4. The annual viscosity of the conveying medium does not exceed 1000CP;

5. The product material is mainly cast iron and cannot be used in highly corrosive or highly corrosive media;

Note: Before selecting or installing the pump, make sure the actual usage conditions of the pump comply with the above terms to ensure the correct use of the product!

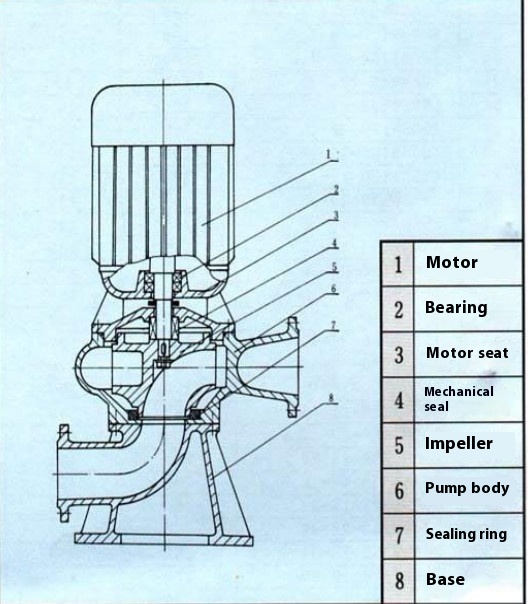

LW vertical non-clogging sewage pump structural diagram:

LW vertical non-clogging sewage pump structure description

The LW vertical non-clogging sewage pump is a single-suction volute pump. The pump is equipped with a non-clogging and anti-winding single (double) large flow channel impeller, which has good passing capacity.

This series of pumps has two structural forms. One is that the motor and the pump are directly coaxial, and the other is connected by a coupling, and the motor adopts a standard vertical motor. The structural diagram is as follows. Each structural form has two base connection forms. One is for inlet horizontal suction, with a corner function. The inlet and outlet can be arranged at 0°, 90°, 180°, and 270° according to the use requirements, which is convenient for pipe management. The second is the axial suction of the inlet, which is convenient for vertical installation.

| LW vertical non-clogging sewage pump performance parameters | ||||||

| caliberLW vertical non-clogging sewage pump model | caliber | Flow | Lift | Speed | Power | Efficiency |

| mm | m3/h | M | r/min | kw | % | |

| LW25-8-22-1.1 | 25 | 8 | 22 | 2900 | 1.1 | 45 |

| LW32-12-15-1.1 | 32 | 12 | 15 | 2900 | 1.1 | |

| LW40-15-15-1.5 | 40 | 15 | 15 | 2900 | 1.5 | 54 |

| LW40-15-30-2.2 | 40 | 15 | 30 | 2900 | 2.2 | 54 |

| LW50-20-7-0.75 | 50 | 20 | 7 | 2900 | 0.75 | 51 |

| LW50-10-10-0.75 | 50 | 10 | 10 | 2900 | 0.75 | 52 |

| LW50-20-15-1.5 | 50 | 20 | 15 | 290 | 1.5 | 53 |

| LW50-15-25-2.2 | 50 | 15 | 25 | 2900 | 2.2 | 54 |

| LW50-18-30-3 | 50 | 18 | 30 | 2900 | 3 | 55 |

| LW50-40-15-4 | 50 | 40 | 15 | 2900 | 4 | 55 |

| LW50-25-32-5.5 | 50 | 25 | 32 | 2900 | 5.5 | 55 |

| LW50-20-40-7.5 | 50 | 50 | 20 | 2900 | 7.5 | 58 |

| LW65-25-15-2.2 | 65 | 25 | 15 | 2900 | 2.2 | 50 |

| LW65-37-13-3 | 65 | 37 | 13 | 2900 | 3 | 57 |

| LW65-25-30-4 | 65 | 25 | 30 | 2900 | 4 | 61 |

| LW65-30-40-7.5 | 65 | 30 | 40 | 2900 | 7.5 | 56 |

| LW65-35-50-11 | 65 | 35 | 50 | 2900 | 11 | 45 |

| LW65-35-60-15 | 65 | 35 | 60 | 2900 | 15 | 65 |

| LW80-60-13-5.5 | 80 | 60 | 13 | 2900 | 5.5 | 67 |

| LW80-40-7-2.2 | 80 | 40 | 7 | 1450 | 2.2 | 59 |

| LW80-43-13-3 | 80 | 43 | 13 | 2900 | 3 | 70 |

| LW80-40-15-4 | 80 | 40 | 15 | 2900 | 4 | 61 |

| LW80-65-25-7.5 | 80 | 65 | 25 | 2900 | 7.5 | 63 |

| LW100-80-10-4 | 100 | 100 | 10 | 1450 | 4 | 65 |

| LW100-110-10-5.5 | 100 | 110 | 10 | 1450 | 5.5 | 65 |

| LW100-100-15-7.5 | 100 | 100 | 15 | 1450 | 7.5 | 68 |

| LW100-80-20-7.5 | 100 | 80 | 20 | 1450 | 7.5 | 65 |

| LW100-100-25-11 | 100 | 100 | 25 | 1450 | 11 | 70 |

| LW100-100-30-15 | 100 | 100 | 30 | 1450 | 15 | 65 |

| LW100-100-35-18.5 | 100 | 100 | 35 | 1450 | 18.5 | 68 |

| LW125-130-15-11 | 125 | 130 | 15 | 1450 | 11 | 72 |

| LW125-130-20-15 | 125 | 130 | 20 | 1450 | 15 | 75 |

| LW150-145-9-7.5 | 150 | 145 | 9 | 1450 | 7.5 | 76 |

| LW150-180-15-15 | 150 | 180 | 15 | 1450 | 15 | 69 |

| LW150-180-20-18.5 | 150 | 180 | 20 | 1450 | 18.5 | 72 |

| LW150-180-25-22 | 150 | 180 | 25 | 1450 | 22 | 78 |

| LW150-130-30-22 | 150 | 130 | 30 | 1450 | 22 | 78 |

| LW150-180-30-30 | 150 | 180 | 30 | 1450 | 30 | 78 |

| LW150-200-30-37 | 150 | 200 | 30 | 1450 | 37 | 73 |

| LW200-300-7-11 | 200 | 300 | 7 | 980 | 11 | 66 |

| LW200-250-11-15 | 200 | 250 | 11 | 1450 | 15 | 64 |

| LW200-250-15-18.5 | 200 | 250 | 15 | 1450 | 18.5 | 73 |

| LW200-400-10-22 | 200 | 400 | 10 | 1450 | 22 | 75 |

| LW200-400-13-30 | 200 | 400 | 13 | 1450 | 30 | 76 |

| LW200-300-15-22 | 200 | 300 | 15 | 1450 | 22 | 76 |

| LW200-250-22-30 | 200 | 250 | 22 | 1450 | 30 | 71 |

| LW200-350-25-37 | 200 | 350 | 25 | 1450 | 37 | 71 |

| LW200-400-30-45 | 200 | 400 | 30 | 1450 | 45 | 74 |

| LW250-600-9-30 | 250 | 600 | 9 | 980 | 30 | 78 |

| LW250-600-12-37 | 250 | 600 | 12 | 1450 | 37 | 76 |

| LW250-600-15-45 | 250 | 600 | 15 | 1450 | 45 | 73 |

| LW250-600-20-55 | 250 | 600 | 20 | 1450 | 55 | 73 |

| LW250-600-25-75 | 250 | 600 | 25 | 1450 | 75 | 71 |

| LW300-800-12-45 | 300 | 800 | 12 | 980 | 45 | 74 |

| LW300-480-15-45 | 300 | 480 | 15 | 1450 | 45 | 66 |

| LW300-800-15-55 | 300 | 800 | 15 | 1450 | 55 | 73 |

| LW300-600-20-55 | 300 | 600 | 20 | 1450 | 55 | 73 |

| LW300-800-20-75 | 300 | 800 | 20 | 1450 | 75 | 75 |

| LW300-950-20-90 | 300 | 950 | 20 | 1450 | 90 | 76 |

| LW300-1000-25-110 | 300 | 1000 | 25 | 1450 | 110 | 76 |

| LW300-1100-10-55 | 300 | 1100 | 10 | 1450 | 55 | 73 |

| LW350-1500-15-90 | 350 | 1500 | 15 | 740 | 90 | 87 |

| LW350-1200-18-90 | 350 | 1200 | 18 | 980 | 90 | 85 |

| LW350-1100-28-132 | 350 | 1100 | 28 | 980 | 132 | 84 |

| LW350-1000-36-160 | 350 | 1000 | 36 | 980 | 160 | 84 |

| LW400-1760-7.5-55 | 400 | 1760 | 7.5 | 980 | 55 | 83 |

| LW400-1500-10-75 | 400 | 1500 | 10 | 980 | 75 | 86 |

| LW400-2000-13-110 | 400 | 2000 | 13 | 980 | 110 | 84 |

| LW400-2000-15-132 | 400 | 2000 | 15 | 980 | 132 | 83 |

| LW400-1700-22-160 | 400 | 1700 | 22 | 980 | 160 | 83 |

| LW400-1500-26-160 | 400 | 1500 | 26 | 980 | 160 | 84 |

| LW400-1700-30-200 | 400 | 1700 | 30 | 980 | 200 | 86 |

| LW400-1800-32-250 | 400 | 1800 | 32 | 980 | 250 | 82 |

| LW500-2500-10-110 | 500 | 2500 | 10 | 740 | 110 | 85 |

| LW500-2600-15-160 | 500 | 2600 | 15 | 740 | 160 | 84 |

| LW500-2400-22-220 | 500 | 2400 | 22 | 740 | 220 | 85 |

| LW500-2650-24-250 | 500 | 2650 | 24 | 740 | 250 | 85 |

Related keywords: non-clogging vertical sewage pump LW vertical sewage pump