CQB heavy duty stainless steel magnetic pump

CQB heavy duty stainless steel magnetic pump It is used in petroleum, chemical industry, metallurgy, pharmaceutical, electroplating, environmental protection and other industries. It can transport flammable, explosive, highly toxic and precious liquids below 100℃. Adopting the principle of magnetic transmission, corrosive media can be transported without leakage. Flow: 3.2-100m3/h Lift: 20-80m Power: 0.75-75KW

The flow-passing part of the pump is made of all stainless steel, which has good corrosion resistance to organic acids, organic compounds, alkalis, neutral solutions and various gases. The running-in of double spiral groove carbon graphite bearings and carbide sleeves It has strong wear resistance and ensures the service life of the product. It is an ideal pump for transporting corrosive media without leakage. Ideal pump for leak-free transport of corrosive media

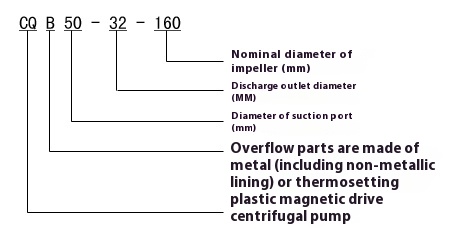

CQB heavy duty stainless steel magnetic pump Model meaning

CQB heavy duty stainless steel magnetic pump Performance parameters

| Model | Flow (m3/h) | Lift (m) | Speed (r/min) | Power (kw) |

| CQB32-20-125 | 3.2 | 20 | 1.1 | |

| CQB32-20-160 | 32 | 1.5 | ||

| CQB40-25-105 | 6.3 | 12.5 | 1.1 | |

| CQB40-25-125 | 20 | 2.2 | ||

| CQB40-25-160 | 32 | 3 | ||

| CQB40-25-200 | 50 | 5.5 | ||

| CQB50-40-85 | 12.5 | 8 | 1.1 | |

| CQB50-32-105 | 12.5 | 1.5 | ||

| CQB50-32-125 | 20 | 3 | ||

| CQB50-32-160 | 32 | 4 | ||

| CQB50-32-200 | 50 | 7.5 | ||

| CQB50-32-250 | 80 | 18.5 | ||

| CQB65-50-125 | 25 | 20 | 2900 | 4 |

| CQB65-50-160 | 32 | 7.5 | ||

| CQB65-40-200 | 50 | 15 | ||

| CQB65-40-250 | 80 | 22 | ||

| CQB80-65-125 | 50 | 20 | 7.5 | |

| CQB80-65-160 | 32 | 15 | ||

| CQB80-50-200 | 50 | 22 | ||

| CQB80-50-250 | 80 | 37 | ||

| CQB100-80-125 | 100 | 20 | 15 | |

| CQB100-80-160 | 32 | 22 | ||

| CQB100-65-200 | 50 | 37 | ||

| CQB100-65-250 | 80 | 55 | ||

| CQB150-150-200 | 200 | 50 | 55 | |

| CQB200-200-400 | 400 | 32 | 1450 | 75 |

Installation and use of CQB heavy duty stainless steel magnetic pump

1. The CQB magnetic drive pump should be installed horizontally and not vertically. The plastic pump body must not bear the weight of the pipeline.

For special requirements for vertical installation, the motor must be facing upwards.

2. When the suction liquid level is higher than the pump axis, just open the suction pipe valve before starting. If the suction liquid level is lower than

the pump axis, the pipeline needs to be equipped with a bottom valve.

3. The CQB magnetic drive pump should be inspected before use. The motor blades must rotate flexibly, there is no jamming or abnormal sound, and

all fasteners must be tightened.

4. Check whether the motor rotation direction is consistent with the magnetic pump steering mark.

5. After the motor starts, slowly open the discharge valve. After the pump enters normal working condition, adjust the discharge valve to the required opening.

6. Before stopping the CQB magnetic drive pump, the discharge valve should be closed first, and then the suction pipe valve should be closed.

Precautions for use of CQB heavy duty stainless steel magnetic pump

1. Since the cooling and lubrication of the magnetic pump bearings depend on the transported medium, idling is absolutely prohibited, and at the same

time, no-load operation caused by restarting after a power outage is avoided.

2. If the transported medium contains solid particles, a filter should be added to the pump inlet: if it contains ferromagnetic particles, a magnetic filter

should be added.

3. When using the CQB magnetic drive pump, the ambient temperature should be less than 40°C, and the motor temperature rise should not exceed 75°C.

4. The transported medium and its temperature should be within the allowable range of the pump material (see attached table for details). The operating

temperature of engineering plastic pumps is <60°C, the operating temperature of metal pumps is <100°C, the delivery and suction pressure is not greater

than 0.2mpa, the maximum working pressure is 1.6mpa, the density is not greater than 1600kg/m3, and the particle size is not greater than 30 × 10-6m2/s

A liquid that does not contain hard particles and fibers.

5. If the conveying liquid is a medium that is easy to precipitate and crystallize, it should be cleaned in time after use and the accumulated liquid in the pump

should be drained.

6. After the magnetic drive pump has been running for 100 hours, the wear of the bearings and end moving rings should be disassembled and the wearing

parts that should not be reused should be replaced.

7. The internal and external magnetic couplings of the CQB magnetic drive pump are made of high-performance permanent magnet materials, which may cause

potential harm to the following devices. Please keep the following devices away from this series of pumps. Such as: pacemakers, credit cards and other magnetic

cards, calculators, computer disks, watches, etc.