CWB magnetic drive vortex pump

CWB magnetic drive vortex pump (magnetic pump for short) is a new product that applies the working principle of permanent magnet coupling to centrifugal pumps. It has reasonable design, advanced technology, full sealing, no leakage, low flow, high head, and corrosion resistance. Characteristics

CWB magnetic drive vortex pump Scope of application

Flow range: 0.72-14.4

Lift range: 20-120

Operating temperature: 120

Transport medium:

Working pressure: 1.6MPa

Current material: stainless steel 304 316 316L

The magnetic pump uses a static seal instead of a dynamic seal, so that the flow-passing parts of the pump are in a completely sealed state, completely solving the problems of running, popping and dripping that cannot be avoided by the mechanical seals of other pumps. The magnetic pump uses corrosion-resistant, high-strength engineering plastics, corundum ceramics, stainless steel, etc. as manufacturing materials, so it has good corrosion resistance and can protect the transported medium from pollution.

Material: 304, 305, 316, 316L

CWB magnetic drive vortex pump Main purpose

The magnetic pump has compact structure, beautiful appearance, small size, low noise, reliable operation and easy use and maintenance. It can be widely used in

chemical industry, pharmaceutical, petroleum, reliable, easy to use and maintain. It can be widely used in chemical industry, pharmaceutical, petroleum, pumping

acid, alkali, oil, rare and precious liquid, venom, volatile liquid, as well as circulating water equipment and filter matching. Especially for pumping leaky, flammable

and explosive liquids, this pump is more ideal.

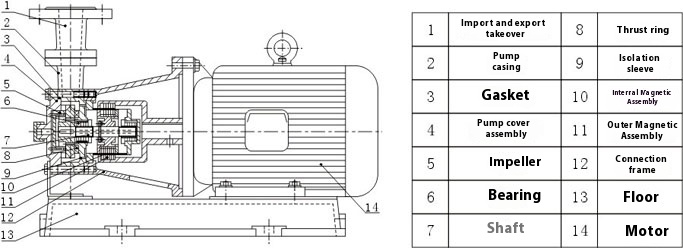

CWB magnetic drive vortex pump Structure diagram

CWB magnetic drive vortex pump Performance parameters

| model | flowQ | Lift H | Speed n | efficiencyη | Motor power |

| (m3/h) | (m) | (r/min) | (%) | (Kw) | |

| CWB20-20 | 0.72 | 20 | 2900 | 22 | 1.1 |

| CWB20-40 | 0.72 | 40 | 2900 | 18 | 1.1 |

| CWB20-65 | 0.72 | 65 | 2900 | 15 | 2.2 |

| CWB25-25 | 1.44 | 25 | 2900 | 26 | 1.1 |

| CWB25-40 | 1.44 | 40 | 2900 | 24 | 1.5 |

| CWB25-75 | 1.44 | 75 | 2900 | 20 | 4 |

| CWB32-30 | 2.88 | 30 | 2900 | 28 | 2.2 |

| CWB32-50 | 2.88 | 50 | 2900 | 26 | 3 |

| CWB32-75 | 2.88 | 75 | 2900 | 22 | 5.5 |

| CWB32-120 | 2.88 | 120 | 2900 | 18 | 7.5 |

| CWB40-40 | 2.88 | 40 | 2900 | 30 | 5.5 |

| CWB40-90 | 2.88 | 90 | 2900 | 26 | 11 |

| CWB50-45 | 2.88 | 45 | 2900 | 30 | 7.5 |

| CWB65-50 | 2.88 | 50 | 2900 | 35 | 15 |

| Note: The materials of the flow-passing parts are 304, 304L, 316, and 316L. Non-standard magnetic vortex pumps can be customized according to customer requirements. | |||||

CWB magnetic drive vortex pump Features

1. High lift. Small flow. Specific speed is generally less than 40

2. Simple structure. Small size. Light weight.

3. It has a self-lubricating circuit to reduce the radial force of the impeller CWB type magnetic drive vortex pump.

4. Use cantilever blades to reduce the radial force of the impeller.

5. As the viscosity of the conveyed medium increases, the efficiency of the pump decreases sharply, so the medium density factor is not greater than 5×10 -6 M 3 /S.

Installation, use and maintenance

CWB magnetic drive vortex pump Installation and use

(1) The magnetic pump should be installed horizontally and should not be installed vertically. For special occasions requiring vertical installation, the motor must be

facing upwards.

(2) When the suction liquid level is higher than the pump axis line, just open the suction pipe valve before starting. If the suction liquid level is lower than the pump

axis line, the pipeline needs to be equipped with a bottom valve.

(3) The pump should be inspected before use. The motor blades must rotate flexibly without jamming or abnormal noise, and all fasteners must be tightened.

(4) Check whether the motor rotation direction is consistent with the magnetic pump steering mark.

(5) Before starting the pump, open the inlet and outlet valves. After the pump enters normal working condition, adjust the discharge valve to the required opening.

(6) Before stopping the pump, the discharge valve should be fully opened, then stopped and then the suction pipe valve should be closed.

CWB magnetic drive vortex pump Precautions for use

(1) Since the cooling and lubrication of the magnetic pump bearings depend on the transported medium, idling operation is absolutely prohibited, and at the same

time, no-load operation caused by restarting after a power outage is avoided.

(2) If the auxiliary medium contains solid particles, a filter should be added to the pump inlet: if it contains ferromagnetic particles, a magnetic filter should be added.

(3) When the pump is in use, the ambient temperature should be less than 40°C, and the motor temperature rise must not exceed 75°C.

(4) The transported medium and its temperature should be less than 100℃, the density should not be greater than 1600kg/m3, and the viscosity should not be greater

than 5×10-6m2/S. It should be a liquid that does not contain hard particles and fibers.

(5) If the conveying liquid is a medium that is prone to precipitation and crystallization, it should be cleaned promptly after use to drain the accumulated liquid in the

pump.

(6) After the magnetic pump has been running for 1500 hours, the wear of the bearings and end moving rings should be disassembled and inspected. If the gap between

the bearings and the sleeve is greater than 0.5~1mm, and the impeller moves 1.5~2mm axially, the bearings and axial movement should be replaced. Moving ring.

(7) This series of pumps must be installed by professionals when used, and must be effectively grounded during installation. See the wiring diagram for details.

(8) The internal and external couplings of this series of pumps are made of high-performance permanent magnet materials, which may cause potential harm to the

following devices. Please keep the following devices away from this series of pumps. Such as: pacemaker, credit card, magnetic card, calculator, computer disk, watch,

etc.