Chemical plants Coal, oil and nuclear power plants Spiral centrifugal pumps

Chemical plants Coal, oil and nuclear power plants Spiral centrifugal pumps

Technical parameters of spiral centrifugal submersible pump

Maximum flow: 13000 m3/h

Maximum lift: 100m

Pipe diameter: DN50-DN1000

Viscosity: 3000 CPS

Maximum self-priming height: 9 mwc

Solid content: 20% slurry, 30% sludge

Application fields of non-clogging large flow channel spiral centrifugal pump

Food waste disposal

activated sludge

agriculture

Beverage industry

activated sludge

Breweries and malting

chemical plant

Coal, oil and nuclear power plants

Stacking and recycling processes

Construction and Tunneling

food processing

Animal glue production

Incinerator

mining industry

oil production

Paper and pulp industry

pet food production

System repair

slaughterhouse

sugar industry

Sewage sludge recycling

Sewage concentration system

sewage treatment plant

Waste incineration power plant

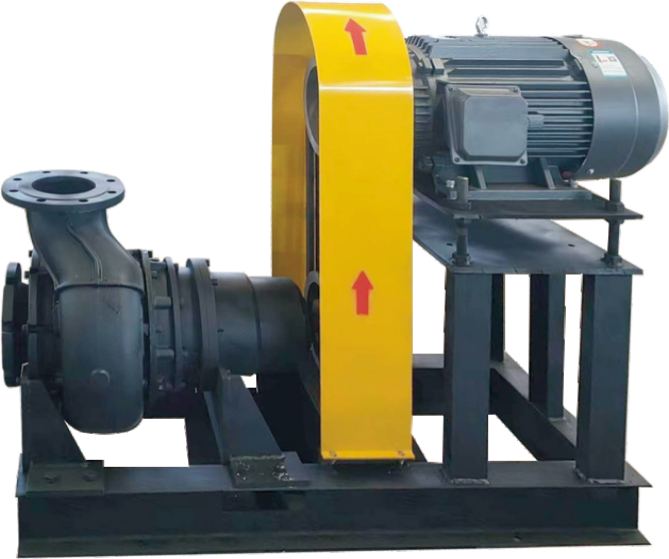

Spiral centrifugal pump submersible pump It is widely used in the chemical, petroleum, pharmaceutical, mining, papermaking, cement, steelmaking, power generation, coal processing industries as well as water supply and drainage systems of urban sewage treatment plants, municipal engineering, construction sites and other industries to remove particles and fiber sewage and dirt from conveyor belts. It can also be used to pump clean water and corrosive media.

Spiral centrifugal pump submersible pump Product use:

This product is widely used in chemical, petroleum, pharmaceutical, mining, papermaking, cement, steelmaking, power generation, coal processing industries, as well as water supply and drainage systems of urban sewage treatment plants, municipal engineering, construction sites and other industries to remove particles and fibers from conveyor belts and fibers. It can also be used to pump clean water and corrosive media.

Spiral centrifugal pump submersible pump Product usage conditions:

1. Three-phase AC power supply with motor rated voltage 380V and frequency 50Hz.

2. The temperature of the conveying medium does not exceed 40°C, the PH value is 4 to 10, the density is less than 1.1×103kg/m3, and the solid phase volume can reach 20%.

Spiral centrifugal pump submersible pump Product performance and structural features:

1. The Q-H curve is steep, the pump has a wide smooth operating area, and the curve drift is small when pumping complex media.

2. High operating efficiency, wide high-efficiency zone, and low operation and maintenance costs.

3. The net suction head is low and the cavitation resistance is strong; the shutdown water level is low, which greatly reduces the cost of pool construction.

4. The power curve sag smoothly and has no overload zone.

5. No clogging or entanglement.

6. Gentle transportation can transport live fish, fruits, vegetables and other fragile substances intact; in the activated sludge return process of the sewage plant, the damage to the bacterial gel mass is only 1/10 of other types of pumps.

7. It can transport media with high solid content, such as mud with a solid content of up to 20%.

8. The advanced Ansys-CFX software is used to optimize the design of hydraulic components, which improves the hydraulic performance of the pump and reaches the advanced level in pump efficiency.

9. Use advanced Ansys software to conduct scientific calculation and analysis of the pump structure, which improves the life of the bearings and mechanical seals and reduces the vibration and noise of the pump.

10. The cable outlet adopts a special structure, which eliminates water leakage, current leakage, short circuit, and stator coil burnout caused by accidental factors such as manual pulling, cable jacket breakage, cable aging, etc., effectively reducing the probability of failure due to water intrusion in the upper part of the machine.

11. There are a number of built-in early warning sensors, and there are protections such as phase loss, short circuit, overcurrent and water level control in the external control cabinet, which can realize remote control and monitoring of the entire system.

12. The bearings are imported famous brand products with reliable structure.

13. The product applies a double sealing structure, which increases the reliability of the sealing.

14. For high-power submersible pumps, a self-circulating cooling system is used, which uses its own impeller water pressure to ensure that the motor is always cooled by water circulation when the water pump is running.

15. The impeller of the water pump adopts a large channel non-blocking impeller, and the blade profile is designed according to streamlines to ensure large channel flow and smooth operation.

16. A replaceable wear-resistant sleeve is installed between the impeller and the lower end of the volute to keep the pump running efficiently.

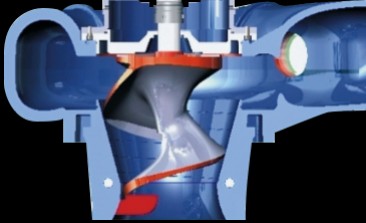

Spiral centrifugal pump submersible pump combines the advantages of centrifugal pumps and positive displacement pumps, redefining the concept and type of high self-priming, high-flow pumps. Each spiral centrifugal pump has a large clearance spiral impeller, which gently pumps the medium into the pump chamber and transfers it to the discharge channel. The open impeller can easily handle large solid particles and long fiber objects. At the same time, the spiral design is very suitable for transporting substances with high solid content and highly viscous liquids. The result is a high-efficiency, low NPSH pump that can save energy and reduce consumption at the same time. Reduce costs.

Working principle of spiral centrifugal pump

The spiral centrifugal pump uses a spiral centrifugal impeller to push the medium into a tapered housing or channel. However, the center force generated by the rotation of the

impeller causes the medium to obtain pressure energy and output it outward.

The design of the open spiral centrifugal impeller has the characteristics of low NPSH (as low as 1mWc), which can reduce equipment maintenance costs caused by cavitation

damage, making the spiral centrifugal pump even if the pipeline condition is not good or is particularly severe for traditional centrifugal pumps. conditions, it can operate normally.

The spiral centrifugal impeller channel has a large blade gap and can pass through large solid particles. Media that are generally less than 80% of the output port diameter,

such as fruits, vegetables, fish, etc., can enter the smooth impeller channel. The combination of the tapered suction port, wide blade clearance and smooth passage of the spiral

centrifugal pump ensures no clogging when the medium is transported from the impeller inlet to the outlet. This design also shortens the transition time of the medium in the

pump body, thereby reducing wear caused by grit, silicon carbide and other similar fine solid suspensions, allowing the pump to handle media with a solid content of up to 30%.

In addition, each screw pump is equipped with an external screw, which can adjust the gap between the impeller and the casing to ensure high pump efficiency and low energy

consumption. In order to adapt to various installation methods of spiral centrifugal pumps, the adjustment of the gap between the impeller and casing of spiral centrifugal pumps

is divided into three adjustment methods.

The impeller has almost no contact with the inhaled object and has extremely low shear forces. Traditional centrifugal pumps have high shear forces due to the contact between

the medium and the impeller tangential surface.

The low shear force of the impeller prevents material damage and is ideal for conveying loose materials without causing breakage, or conveying crystallized fluids (such as activated

carbon) while retaining their original structure to the greatest extent possible.

The spiral submersible pump has better non-clogging performance than traditional pumps in conveying long fiber suspended media, thereby reducing dredging costs. The ultra-fast soft transition ability and low-shear force pumping function greatly reduce the damage of abrasive liquids to the pump body and the damage of equipment to polymer substances. Therefore, screw submersible pumps are very suitable for conveying slurry and sludge in food waste processing, agricultural waste processing, biological waste energy processing, beer and food manufacturing and construction industries, mining, pulp and paper, pet food processing and wastewater treatment. .

The design, development, and manufacturing of spiral centrifugal pumps focus on high hydraulic efficiency and low operating costs to reduce the total cost of use.

The specially designed impeller ensures high efficiency and low energy consumption when handling viscous liquids. The combination of ultra-short transition capacity, reinforced impeller and high-quality housing effectively reduces equipment wear. The ultra-low NPSH value reduces the maintenance costs caused by cavitation damage.