QY-S All stainless steel oil-immersed submersible electric pump

QY-S All stainless steel oil-immersed submersible electric pump

QY oil submersible electric pump is a power drainage and irrigation equipment that integrates water pump and three-phase asynchronous motor.

It has reliable waterproof sealing performance, small size, light weight, no need for pump room, no need for water conduit, and convenient use,

maintenance and management. Common models are: QY100-4.5-2.2, QY65-7-2.2, QY40-12-2.2, QY10-32-2.2, QY8.4-40/2-2.2, QY65-10-3, QY40-16-3,

QY12.5-40-3, QY8.4-50/2-3, QY10-54/3-3, QY160-6-4, QY65-1 4-4, QY25-32-4, QY10-60/2-4, QY12.5-50-4, QY10-72/4-4, QY65-20-5.5, QY10-84/3-5.5,

QY25-40-5.5, QY200-12-7.5, QY65-25-7.5, QY10-110/4-7.5, QY65-42/2-11 and other series

QY-S All stainless steel oil-immersed submersible electric pump Product Overview

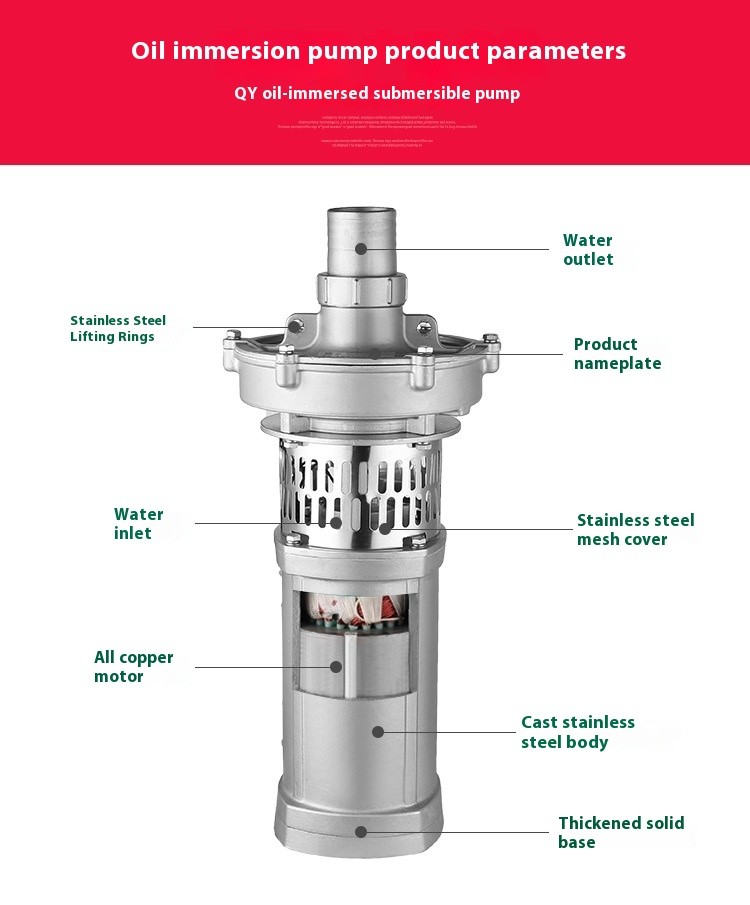

The QY series oil-filled small submersible electric pump (hereinafter referred to as electric pump) consists of three parts: water pump, seal, and electric motor. The water pump is located at the upper part of the electric pump, which is a centrifugal or axial flow structure; the motor is located at the lower part of the electric pump, which is an oil-filled three-phase asynchronous motor; the water pump and the motor are sealed with an internally installed mechanical seal box, and the fixed stop seal is a "O"-shaped oil-resistant rubber seal ring for static sealing.

1. The QY all stainless steel oil-filled submersible electric pump has a beautiful appearance and small size. A unique floating oil bag is installed inside the lower part of the pump. The temperature of the electric pump increases and the oil bag is lowered to prevent the temperature from rising and bursting, adjust the internal and external pressures, and ensure the safety and reliability of the pump operation.

2. The mechanical seal adopts fluoroelastic double-end seal, and the outdoor mechanical seal adopts a single-sided mechanical seal to effectively protect the motor from the burner caused by water inlet.

3. It adopts F-class insulated motors, tapered bearings, etc. designs, which can extend the life of the electric pump.

QD dry submersible electric pump is a down-pump electric power drainage and irrigation equipment that is integrated into a water pump, sealed part and

submersible motor. Due to its small size and light weight, it is widely used in rural underground water pumping, farmland drainage and irrigation, and household

water automation. It can also be used to remove industrial water accumulation, construction water supply and drainage, fountain engineering and other industries.

Commonly used models include: QD3-30/2-0.75, QD6-20/2-0.75, QD3-45/3-1.1, QD6-32/3-1.1, QD3-65/4-1.5, QD6-35/2-1.5, QD6-42/4-1.5, QD10-26/2-1.5, QD2-20/2-1.5

and other series.

QY-S All stainless steel oil-immersed submersible electric pump application range

1. Drainage, well irrigation and sprinkler irrigation of farmlands;

2. Lift water downhole and deliver water to the water tower;

3. Drainage and flood prevention;

4. Drainage at the bottom of the ship bin;

5. Urban construction and industrial and mining water supply and drainage.

QY-S All stainless steel oil-immersed submersible electric pump Working conditions

Features

1. The working medium is a non-corrosive liquid, the volume ratio of particles in the medium shall not exceed 0.10%, and the particle size shall not exceed 0.20mm.

2. The medium temperature shall not exceed 40℃.

3. The pH values of the conveying medium are 304 (4-10), 316 (4-13);

4. The electric pump should be used within the range of use near the rated head. And it is completely immersed in water for use. The diving depth should not exceed 3m and the deepest depth should not exceed 5m.

5. The electric pump is more than 0.5m from the bottom of the water, but it cannot be trapped in the mud.

6. The power supply frequency is three-phase 50HZ, and the voltage fluctuation range is 0.9-1.1 times the rated value.

QY-S All stainless steel oil-immersed submersible electric pump Notes on using:

1. The specifications and performance of the submersible pump should comply with the actual use conditions and should be carefully checked before use.

2. The inner diameter of the outlet pipe equipped with the submersible pump should be consistent with the diameter of the electric pump.

3. The power supply capacity should be above 5.5 kVA, three-phase, 380 volts, and 50 Hz AC.

4. When the submersible pump is live or pumped, do not wash things nearby, swim or work, and do not let livestock get into the water nearby, to prevent electric shock accidents in case of electric pump leakage.

5. Submersible pumps shall not suck water or mud water with a large amount of sand.

6. If the submersible pump suddenly stops rotating, or the water volume suddenly decreases significantly, the machine must be shut down for inspection, and the power must be cut off first, and then transport and disassemble.

7. The electric pump should be equipped with a motor protection switch (our factory has allocated the operation current of the protection switch has been set and the user may not change it by himself.

8. It is not allowed to lift the cable of the electric pump hard at any time. When using the cable, check the cable thoroughly and replace it with a new one when it is found to be damaged.

9. Voltage fluctuations are allowed to be between 342 and 418 volts. If the electric pump uses a ground far away from the power supply, the cross-sectional area of the wire should be appropriately thickened.

10. A yellow-green two-color core wire with grounding mark in the lead-out cable must be grounded. If there is no fixed ground wire, you can use a 2-meter metal rod to bury it on the banks of rivers and lakes, beside ditches or in wet soil as ground wires.

11. Before use, check whether the upper and lower oil hole screws are loose and oil leakage. The M8 screw on the outlet box is specially designed for pressure testing in our factory, and users are strictly prohibited from loosening themselves.

12. Before operation, use a 500V megohmmeter to measure the insulation resistance of the motor stator winding to the ground in a cold state. The minimum must not be less than 5MΩ, otherwise it cannot be used and it should be driven out before use.

13. Before use, turn idle on land for 1 min0 to check whether the electric pump is operating normally and whether the steering is correct.

14. The electric pump must not be dehydrated and operated. When working the electric pump, be careful to check that the water level drops and do not allow the electric pump to operate on the water surface. The submersible depth range of the electric pump is 0.5 to 3 meters.

15. The electric pump must not be trapped in mud or placed horizontally. It is recommended that the electric pump use bamboo baskets or wire baskets externally to prevent aquatic weeds and debris from clogging the water pump impeller.

16. After the electric pump is turned on, if the water output is small or no water output is found, it means that the direction of rotation of the electric pump is reversed. The power supply should be cut off and any two-phase position in the three-phase core wire should be exchanged before driving.

QY-S All stainless steel oil-immersed submersible electric pump The main reasons for burnout of the stator winding:

1) Two-phase operation of submersible pump motor:

A. One phase of the three-phase power supply is due to poor contact between the switch contacts or cable connectors;

B. The ground wire and the phase wire are connected incorrectly;

C. One of the cables is not connected well and disconnected or contacts are poor.

2) The grinding block in the entire sealing box is severely worn, causing water leakage to the inside of the motor, resulting in a short circuit between turns or phases of the stator winding.

3) The submersible pump is trapped in mud and has poor heat dissipation.

4) The dehydration and operation time of the submersible pump is too long.

Motor overload operation: A. The output network voltage is too low, or the cable is too thin and long, and the voltage drop is too large; B. The low-head pump (QY-4.5-meter pump) type uses a head that is too high exceeds the specified, and the high-head pump (head above 15 meters) is too low, less than the specified 70%; C. The sand content is too much, the specific gravity of the water quality is too high, or mud and water is inserted; D. The pump impeller is stuck by external debris, and the motor is in three-phase braking.

5) After the cable is damaged, the stator winding becomes damp.

6) The two ends of the stator winding rub against the upper and lower covers or housings, causing insulation damage, causing the winding to break down to the ground.

7) During assembly, the image glue seal ring on the upper and lower covers was accidentally cut off by the stop or fell off into the motor; after assembly, it did not undergo a 0.2MPa air pressure test, and water was seriously injected into the motor during use.

8) The submersible pump is turned on and stopped too frequently.

9) The submersible pump was hit by lightning.

| QY-S All stainless steel oil-immersed submersible electric pump Performance parameters | ||||||

| model | flow | head | Pipe | power | Speed | voltage |

| m3/h | m | mm | KW | r/min | V | |

| QY8.4-40-2.2 | 8.4 | 40 | 50 | 2.2 | 2860 | 380 |

| QY15-26-2.2 | 15 | 26 | 50 | |||

| QY25-17-2.2 | 25 | 17 | 63 | |||

| QY40-12-2.2 | 40 | 12 | 76 | |||

| QY65-7-2.2 | 65 | 7 | 100 | |||

| QY100-4.5-2.2 | 100 | 4.5 | 150 | |||

| QY15-36-3 | 15 | 36 | 50 | 3 | ||

| QY25-26-3 | 25 | 26 | 63 | |||

| QY40-16-3 | 40 | 16 | 76 | |||

| QY65-10-3 | 65 | 10 | 100 | |||

| QY100-6-3 | 100 | 6 | 150 | |||

| QY160-4-3 | 160 | 4 | 150 | |||

| QY260-3.5-4 | 260 | 3.5 | 200 | 4 | ||

| QY200-4.5-4 | 200 | 4.5 | 150 | |||

| QY65-14-4 | 65 | 14 | 100 | |||

| QY40-21-4 | 40 | 21 | 76 | |||

| QY25-32-4 | 25 | 32 | 63 | |||

| QY25-38/2-4 | 25 | 38 | 63 | |||

| QY12.5-50-4 | 12.5 | 50 | 50 | |||

| QY12.5-72/4-4 | 12.5 | 72 | 50 | |||

| QY25-45/3-5.5 | 25 | 45 | 63 | 5.5 | ||

| QY10-78/3-5.5 | 10 | 78 | 50 | |||

| QY200-8-5.5 | 200 | 8 | 150 | |||

| QY260-6-5.5 | 260 | 6 | 200 | |||

| QY65-18-5.5 | 65 | 18 | 100 | |||

| QY40-28-5.5 | 40 | 28 | 76 | |||

| QY25-40-5.5 | 25 | 40 | 63 | |||

| QY18-64/3-5.5 | 18 | 64 | 63 | |||

| QY65-28-7.5 | 65 | 28 | 100 | 7.5 | ||

| QY40-38-7.5 | 40 | 38 | 76 | |||

| QY25-50-7.5 | 25 | 50 | 63 | |||

| QY200-10-7.5 | 200 | 10 | 150 | |||

| QY10-100/4-7.5 | 10 | 110 | 50 | |||

| QY260-8-7.5 | 260 | 8 | 200 | |||

| QY18-126/6-11 | 18 | 126 | 63 | 11 | ||

| QY10-160/6-11 | 10 | 160 | 50 | |||