CQB-F fluoroplastic magnetic drive pump

CQB-F fluoroplastic magnetic drive pump Made of polyvinylidene fluoride, magnetic pumps produced with this material have a wide range of uses, strong corrosion resistance, high mechanical strength, no aging, and no toxin decomposition.

CQB-F fluoroplastic magnetic drive pump Model meaning

For example: CQB50-32-160F

CQB-magnetic drive centrifugal pump

50-suction port diameter (mm)

32-Discharge port diameter (mm)

160-impeller nominal diameter (mm)

F-Fluoroplastic

CQB-F fluoroplastic magnetic drive pump Performance parameters

Flow: 1.8-100m3/h

Lift: 8-32m

Motor power: 0.12-18.5KW

Speed: 2900r/min

Operating temperature: -20℃ to 100℃.

CQB-F fluoroplastic magnetic drive pump Features

The design of the fluoroplastic magnetic pump not only has the advantages of ordinary magnetic pumps such as compact structure, beautiful appearance, small

size, low noise, reliable operation, etc., but its flow-passing parts are all made of the "King of Plastics" (King of Plastics) with excellent corrosion resistance in the

world. Fluorine plastic), the isolation sleeve is made of special materials, has high strength mechanical properties, and eliminates the magnetic eddy current

phenomenon that exists in ordinary magnetic pumps. Therefore, the fluoroplastic magnetic pump can transport corrosive media such as acids, alkalis, and

oxidants of any concentration (strength) without being damaged. The leak-proof design eliminates the shaft seal and uses magnetic coupling to drive indirectly,

completely eliminating the trouble of dripping and never polluting the use site.

CQB-F fluoroplastic magnetic drive pump Classification: At present, the fluoroplastic magnetic pumps produced by domestic manufacturers mainly include: CQB fluoroplastic magnetic pump, ZMD

fluoroplastic self-priming magnetic pump, IMD fluoroplastic magnetic drive pump, etc. Because the flow-passing part of the pump is made of "fluoroplastic

alloy". It can continuously transport corrosive media such as acids, alkalis, and strong oxidants of any concentration without being damaged. The CQB-F fluoroplastic

magnetic pump has a unique design. It does not require mechanical shaft seals and is absolutely leak-proof. The liquid flow parts are made of fluoroplastics, ceramics,

fluororubber and other materials. The pump body shell is fixed with metal materials, so the pump body is sufficient to support the pipeline. weight, maintenance and

convenience.

CQB-F fluoroplastic magnetic drive pump Working principle

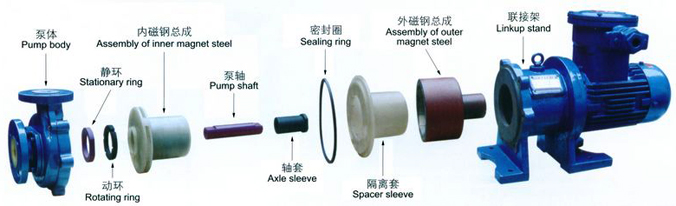

The driving device adopts an active magnet coupling and is directly mounted on the motor shaft. The pump chamber is completely enclosed and indirectly drives the impeller with magnets on the pump shaft to rotate through magnetic coupling. The structure is compact, safe and energy-saving. Sturdy and durable pump body structure Although the liquid-contacting part is made of fluoroplastic, the pump casing is made of metal, so the pump body is strong enough to withstand the weight of the pipeline and withstand mechanical impact. Fluoroplastic magnetic pump consists of three parts: pump, magnetic transmission and electric motor. The key component of the magnetic actuator is composed of an outer magnetic rotor, an inner magnetic rotor and a non-magnetic isolation sleeve. When the motor drives the outer magnetic rotor to rotate, the magnetic field can penetrate the air gap and non-magnetic materials, driving the inner magnetic rotor connected to the impeller to rotate synchronously, realizing contactless transmission of power and converting the dynamic seal into a static seal. Since the pump shaft and internal magnetic rotor are completely sealed by the pump body and isolation sleeve, the problem of "running, popping, dripping, and leaking" is completely solved, and the leakage of flammable, explosive, toxic, and harmful media through the pump seal in the refining and chemical industry is eliminated. potential safety hazards, effectively ensuring the physical and mental health and safe production of employees.

CQB-F fluoroplastic magnetic drive pump Main purpose

This product is widely used in: petrochemical industry, acid and alkali production, non-ferrous metal smelting, pickling process of automobile manufacturing, rare earth separation, pesticides, dyes, medicine, paper making, electroplating, radio and other industries.

CQB-F fluoroplastic magnetic drive pump Structure diagram

CQB-F fluoroplastic magnetic drive pump Installation, use and maintenance

1. The pump should be inspected before use. The motor fan blades must rotate flexibly, there is no jamming or abnormal noise, and all fasteners must be tightened.

2. After the motor of the CQB-F2 fluorine-lined magnetic pump is started, slowly open the discharge valve. After the pump enters normal working condition, adjust the

discharge valve to the required opening.

3. The CQB-F2 fluorine-lined magnetic pump should be installed horizontally and not vertically. The pump body must not bear the weight of the pipeline. For special

requirements for vertical installation, the motor must be facing upwards.

4. Check whether the rotation direction of the motor of the CQB-F2 fluorine-lined magnetic pump is consistent with the steering mark of the magnetic pump.

5. When the suction liquid level is higher than the axis center line of the CQB-F2 fluorine-lined magnetic pump, just open the suction pipeline valve before starting.

If the suction liquid level is lower than the pump axis center line, the pipeline needs to be equipped with a bottom valve.

6. Before the CQB-F2 fluorine-lined magnetic pump stops working, the discharge valve should be closed first, and then the suction pipe valve should be closed.

CQB-F fluoroplastic magnetic drive pump Performance parameters

| model | flow (m3/h) | Lift (m) | power(kw) | Voltage(V) |

| CQB16-16-80F | 1 | 8.5 | 0.12 | 220 |

| 1.8 | 8 | |||

| 2.2 | 7 | |||

| CQB20-20-100F | 1.8 | 12.5 | 0.37 | 220 |

| 3 | 12 | |||

| 3.6 | 10.5 | |||

| CQB16-16-80F | 1 | 8.5 | 0.12 | 380 |

| 1.8 | 8 | |||

| 2.2 | 7 | |||

| CQB20-20-100F | 1.8 | 12.5 | 0.37 | 380 |

| 3 | 12 | |||

| 3.6 | 10.5 | |||

| CQB32-25-125F | 1.9 | 20.8 | 1.1 | 380 |

| 3.2 | 20 | |||

| 3.8 | 19 | |||

| CQB32-25-160F | 1.9 | 20.8 | 1.5 | 380 |

| 3.2 | 32 | |||

| 3.8 | 19 | |||

| CQB40-32-115F | 3.8 | 16 | 1.1 | 380 |

| 6.3 | 15 | |||

| 7.5 | 13 | |||

| CQB40-32-145F | 3.8 | 26 | 2.2 | 380 |

| 6.3 | 25 | |||

| 7.5 | 22.5 | |||

| CQB40-32-160F | 3.8 | 34 | 3 | 380 |

| 6.3 | 32 | |||

| 7.5 | 28 | |||

| CQB50-40-125F | 7.5 | 22 | 2.2 | 380 |

| 12.5 | 20 | |||

| 15 | 18.5 | |||

| CQB50-40-160F | 7.5 | 34 | 3 | 380 |

| 12.5 | 32 | |||

| 15 | 29 | |||

| CQB65-50-125F | 15 | 22 | 4 | 380 |

| 25 | 20 | |||

| 30 | 18.5 | |||

| CQB65-50-160F | 15 | 34 | 5.5 | 380 |

| 25 | 32 | |||

| 30 | 29.5 | |||

| CQB80-65-125F | 30 | 22.5 | 7.5 | 380 |

| 50 | 20 | |||

| 60 | 18 | |||

| CQB80-65-160F | 30 | 34 | 11 | 380 |

| 50 | 32 | |||

| 60 | 29 |