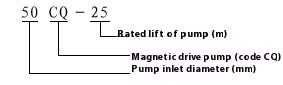

CQ stainless steel magnetic drive pump

CQ stainless steel magnetic drive pump Model meaning

CQ stainless steel magnetic drive pump Overview

CQ stainless steel magnetic drive pump are made of stainless steel (304, 316, 316L). They are widely used in petroleum, chemical industry, pharmaceutical, electroplating, environmental protection, water treatment, national defense and other departments. They are suitable for transporting flammable, explosive and toxic materials. Ideal equipment for liquids and precious liquids, it is the best choice to create a leak-free and pollution-free civilized workshop. Applicable temperature of magnetic drive pump: -20℃~100℃.

CQ stainless steel magnetic pump is a new type of pump that uses the working principle of permanent magnet coupling to transmit torque without contact. When the

prime mover drives the outer magnetic steel rotor, the inner magnetic steel rotor is driven to rotate synchronously through the action of the magnetic field, and the inner

magnetic steel rotor and The impellers are connected together to achieve the purpose of driving the impellers to rotate without contact. Since the liquid is enclosed in a

static isolation sleeve, the magnetic pump is a fully enclosed, leak-free pump type, thus completely eliminating the inevitable problems of running, popping, dripping and

leaking of mechanically sealed centrifugal pumps.

In many fields such as petroleum, chemical industry, pharmaceuticals, electronics, etc., more and more manufacturers require a leak-free process environment for the media

they transport, and there is an urgent need to choose the ideal pump type. The CQ series magnetic pump produced by our company absorbs The leading domestic and

foreign magnetic pump production technologies, new materials, and new processes have successfully solved the current technical problems of easily damaged isolation

sleeves, impellers and other components of domestic magnetic drive pumps, making their performance more perfect. CQB, IMD, CQ, CQF series magnetic pumps have

been tested by long-term productive and continuous operation of the users. More and more users are convinced that they have chosen a safe and reliable pump model.

We will continue to provide more users with more Excellent service.

CQ stainless steel magnetic drive pump Leak-proof design

The static seal is used instead of the dynamic seal, and the magnetic coupling is used to drive indirectly, which completely eliminates the trouble of dripping and never pollutes the use site. The magnetic drive pump is an ideal pump that eliminates run-off, pop-up, dripping and leakage in the chemical process, eliminates environmental pollution, creates a "leak-free workshop" and "leak-free factory", and achieves safe and civilized production.

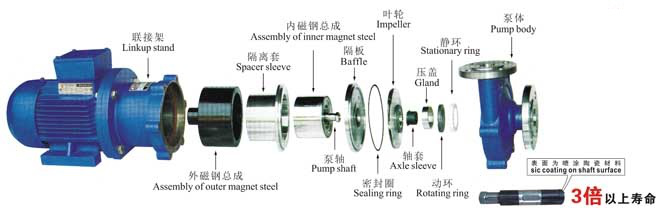

Operating principle

CQ stainless steel magnetic drive pump The driving device uses an active magnet coupling to be mounted directly on the motor shaft. The pump chamber is completely enclosed and indirectly drives the impeller on the rotor assembly to rotate through magnetic coupling.

CQ stainless steel magnetic drive pump Product use

The magnetic pump has compact structure, beautiful appearance, small size, low noise, reliable operation, and easy use and maintenance. It can be widely used in chemical industry, pharmaceutical, petroleum, electroplating, food, national defense, scientific research institutions, metallurgy, dyestuffs and other units to pump acids, alkalis, oils, rare and valuable liquids, venoms, volatile liquids, as well as circulating water equipment and filters. Matching. Especially the pumping of leaky, flammable and explosive liquids. It is more ideal equipment for explosion-proof motor to choose this pump.

CQ stainless steel magnetic drive pump Structure diagram

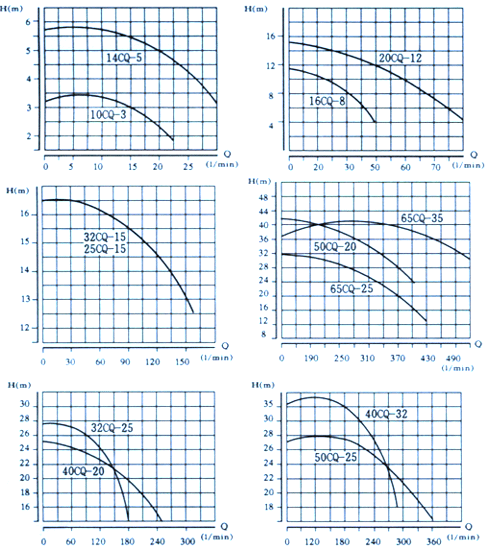

CQ stainless steel magnetic drive pump Performance parameters

CQ stainless steel magnetic drive pump Installation and use

1. The magnetic pump should be installed horizontally and not vertically. The plastic pump body must not bear the weight of the pipeline. For special occasions requiring

vertical installation, the motor must be facing upwards.

2. When the suction liquid level is higher than the pump shaft center line, just open the suction pipe valve before starting. If the suction liquid level is lower than the pump

shaft retraction line, the pipeline needs to be equipped with a bottom valve.

3. The pump should be inspected before use. The motor blades must rotate flexibly without jamming or making strange sounds, and all fasteners must be tightened.

4. Check whether the motor rotation direction is consistent with the magnetic pump steering mark.

5. After the motor starts, slowly open the discharge valve. After the pump enters normal working condition, adjust the discharge valve to the required opening.

6. Before the pump stops working, the discharge valve should be closed first, and then the suction pipe valve should be closed.

CQ stainless steel magnetic drive pump Precautions for use

1. Because the cooling and lubrication of the magnetic pump bearings depend on the transported medium, idling operation is absolutely prohibited, and at the same time,

avoid idling operation caused by restarting after a power outage during work.

2. If the conveyed medium contains solid particles, a filter should be added to the pump inlet: if it contains ferromagnetic particles, a magnetic filter should be added.

3. When the pump is in use, the ambient temperature should be less than 40°C, and the motor temperature rise should not exceed 75°C.

4. The transported medium and its temperature should be within the allowable range of the pump material. The operating temperature of the engineering plastic pump

is <60°C, and the operating temperature of the metal pump is <100°C. The auxiliary suction pressure is not greater than 0.2MPa, the maximum working pressure is 1.6MPa,

the density is not greater than 1600^kg/m3, and the particle size is not greater than 30 10-6㎡/S liquid without hard particles and fibers.

5. If the conveying liquid is a medium that is prone to precipitation and crystallization, it should be cleaned promptly after use to drain the accumulated liquid in the pump.

6. After the magnetic pump has been running for 500 hours, the bearings and end moving rings should be disassembled and inspected for wear and inertia. If the gap

between the bearings and the sleeve is greater than 0.5~1mm, and the impeller moves axially by 1.5~2mm, the bearings and bearings should be replaced. Axial moving ring.

CQ stainless steel magnetic drive pump Performance parameters

model | caliber | flow (m3/h) | Lift (m) | Motor power (kW) | Voltage (V) | Material | |

import (mm) | exit (mm) | ||||||

14CQ-5 | 14 | 10 | 1.2 | 5 | 0.12 | 220/380 | 不 锈 钢 |

16CQ-8 | 16 | 12 | 1.8 | 8 | 0.18 | 220/380 | |

20CQ-12 | 20 | 12 | 3 | 12 | 0.37 | 220/380 | |

25CQ-15 | 25 | 20 | 5.4 | 15 | 1.1 | 380 | |

32CQ-15 | 32 | 25 | 6.5 | 15 | 1.1 | 380 | |

32CQ-25 | 32 | 25 | 4.8 | 25 | 1.1 | 380 | |

40CQ-20 | 40 | 32 | 10 | 20 | 2.2 | 380 | |

40CQ-32 | 40 | 32 | 11.5 | 32 | 4 | 380 | |

50CQ-25 | 50 | 40 | 14.4 | 25 | 4 | 380 | |

50CQ-32 | 50 | 40 | 13.2 | 32 | 4 | 380 | |

50CQ-50 | 50 | 32 | 7.8 | 50 | 5.5 | 380 | |

65CQ-25 | 65 | 50 | 16.8 | 25 | 5.5 | 380 | |

65CQ-32 | 65 | 50 | 25 | 32 | 7.5 | 380 | |

80CQ-32 | 80 | 65 | 50 | 32 | 11 | 380 | |

50CQ-50 | 80 | 65 | 50 | 50 | 15 | 380 | |

100CQ-32 | 100 | 80 | 60 | 32 | 15 | 380 | |

100CQ-50 | 100 | 80 | 60 | 50 | 18.5 | 380 | |

注:表中16CQ-8---100CQ-50都可配防爆电机 | |||||||