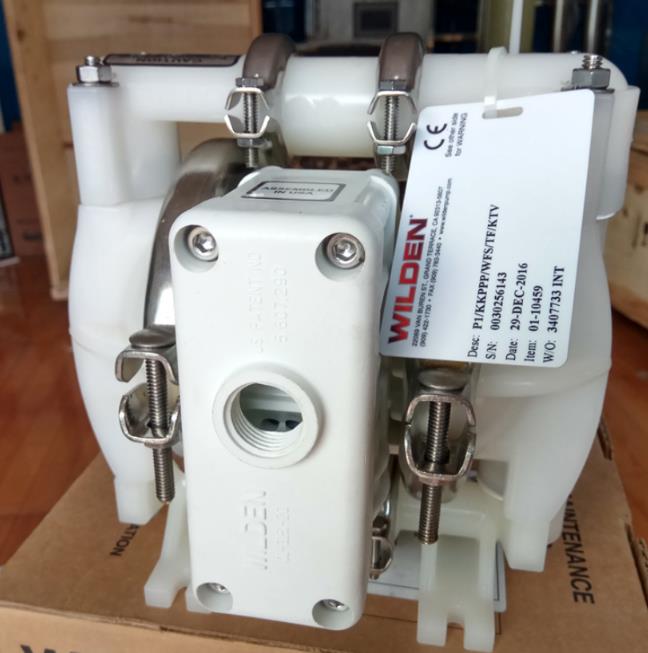

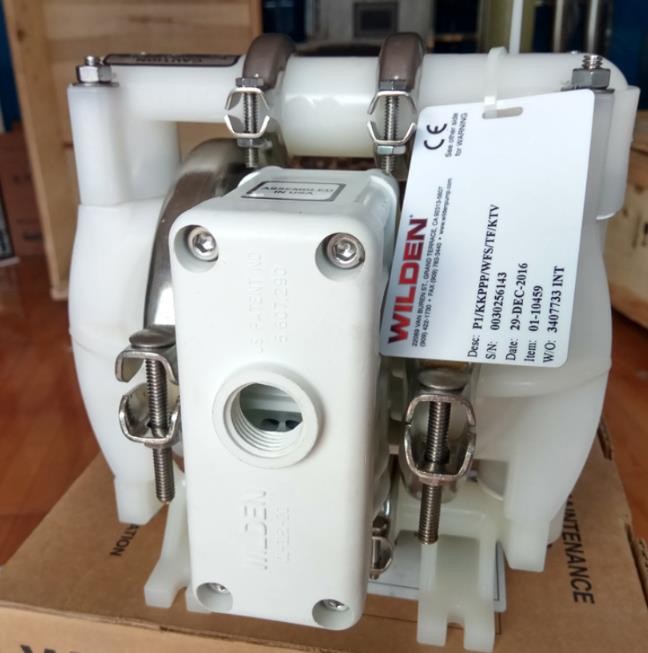

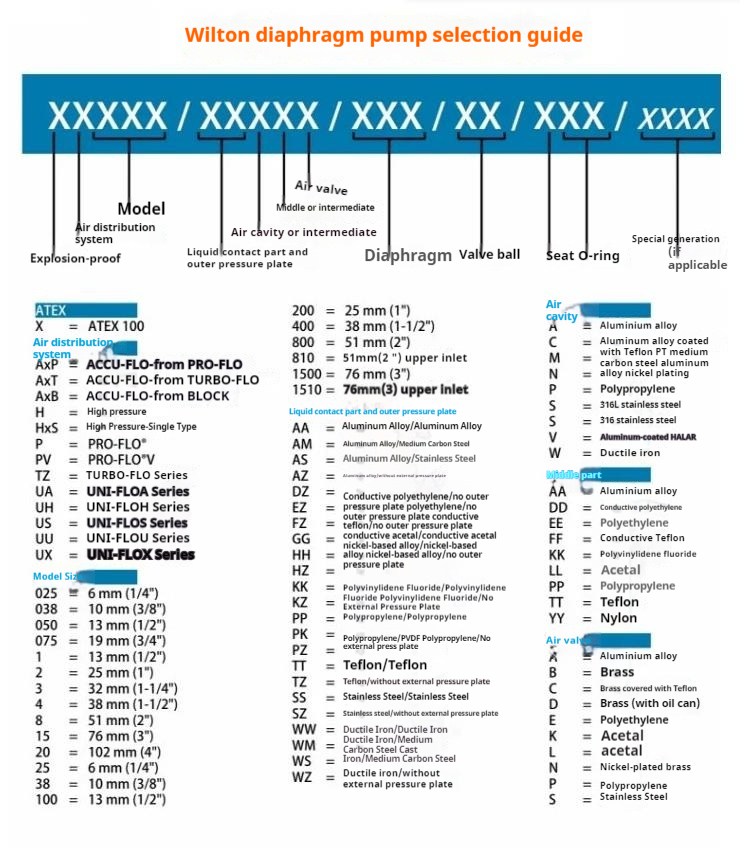

Wilden Small Pneumatic Diaphragm Pump PRO-Fio Bolt Pump 0.5PRO-Flo® Series Plastic Bolt Pumps Diaphragm Ball Seat Accessories

Wilden Small Pneumatic Diaphragm Pump PRO-Fio Bolt Pump 0.5PRO-Flo® Series Plastic Bolt Pumps Diaphragm Ball Seat Accessories

Basic Info.

Product Description

air intake

1/8" FNPT

Feed port

6 mm (1/4")

Discharge port

6 mm (1/4")

Connection type

NPT/BSPT (thread)

Maximum suction height

PTFE - 1.9 m (6.2') dry, 9.3 m (30.6') wet

maximum flow

PTFE - 16.7 lpm (4.4 gpm)

maximum pressure

8.6 bar (125 psi)

Maximum particle size

0.7 mm (1/32'')

Displacement per stroke *

PTFE - 0.04 L (0.01 gal)

*1 cycle = 2 strokes

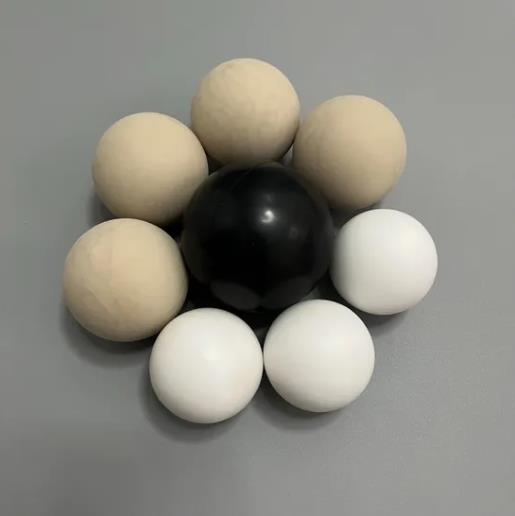

Wilden pneumatic diaphragm pump original diaphragm product features: corrosion resistance, high temperature resistance, good stability, no sticking, self-priming Optional elastomer materials: nitrile rubber, neoprene, EPDM, Wil-Flex, Saniflex, polyurethane, PTFE

Wilden pneumatic diaphragm pump TZ8/SSAAB/TNU/TF/STF/0014 Wilden repair kit

WILDEN high-pressure pneumatic diaphragm pump features: Bolt design can be highly leak-proof Sliding seal capability Single-head or double-head positive displacement technology No lubricating oil required for operation

Features:

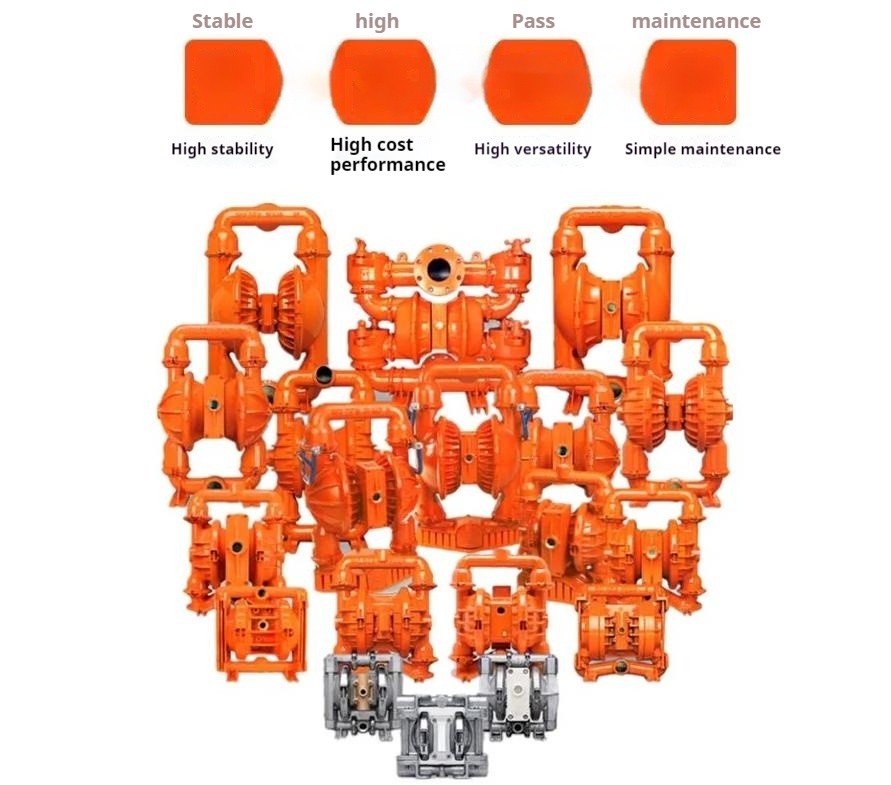

Patented design of the unbalanced air valve, unbalanced piston that will not stop, no dead center, plastic self-lubricating air system, no need to add lubricating oil, minimal energy consumption, extremely low compressed air leakage, special and fast exhaust structure , fully ensuring that the air valve does not freeze and improving air utilization. The number of parts and wearing parts in a single pneumatic diaphragm pump is the smallest in the industry. The unique clamp design, quick and easy disassembly and assembly, and the patented rib design make the WILDEN diaphragm the one with the longest lifespan and highest temperature resistance in the industry. Passed ISO9001 certification and European Community CE certification.

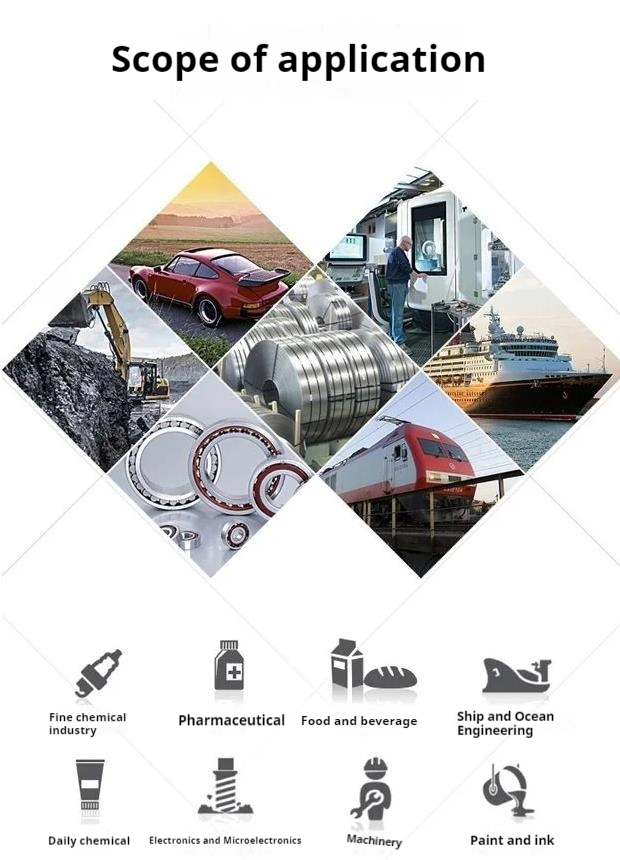

Product applications - solvents, acids, corrosive liquids, high-viscosity liquids, high-pressure transmission, large solid particle transmission, abrasive media.

Shell material........................................ ..Polyethylene, polyvinylidene fluoride

Flow parts (pump center body part)............. Acetal, polypropylene

Air valve material................................................Acetal Aldehyde, polypropylene

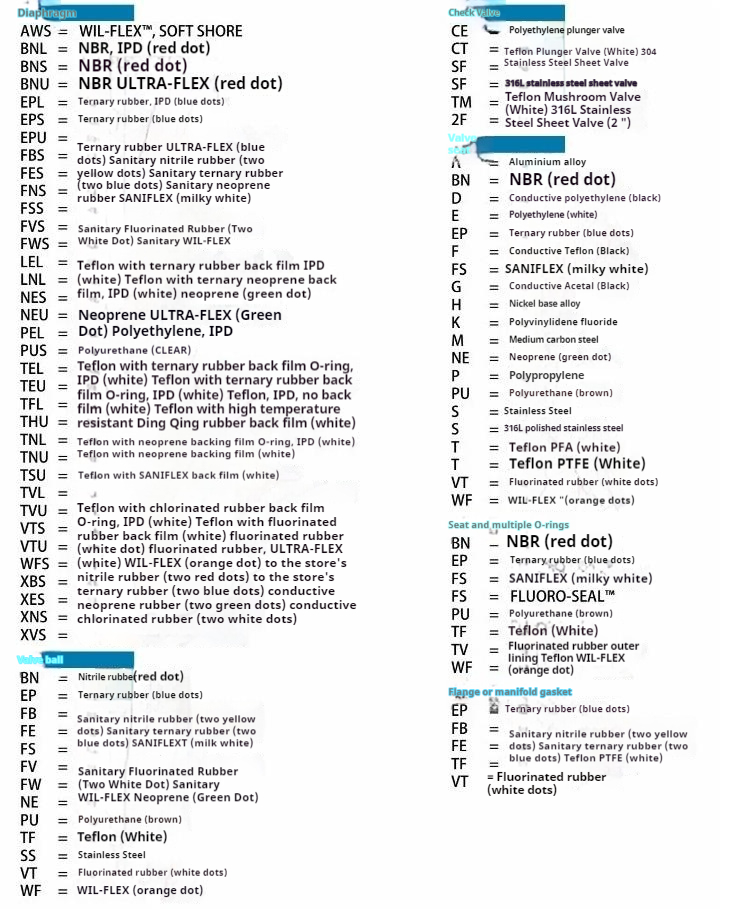

Diaphragm material........................................ .NBR, Wil-FlexTM

Advantages of pneumatic diaphragm pumps

The design of the unbalanced valve, the unbalanced piston that will not stop, and absolutely no dead center;

Plastic self-lubricating air system, no need for oil lubrication;

Low energy consumption and extremely low compressed air leakage;

The special rapid exhaust structure fully ensures that the air valve does not freeze and improves air utilization;

The number of parts and wearing parts in a single pump is the lowest in the industry. The unique clamp design makes disassembly and assembly quick and convenient;

The unique reinforced rib design makes the WILDEN diaphragm the longest-lasting and high-temperature resistant in the industry;

Passed ISO9001 certification and European Community CE certification.

General advantages of pneumatic diaphragm pumps

There is no spark, it can run dry, and it can start working by self-priming without complicated control. It is easy to operate and the self-priming height can reach 6M;

Strong acid, strong alkali, and strong organic solvent liquid media with different characteristics can be transported by selecting the materials of the pump shell and diaphragm;

No dynamic seal, no contamination of materials, low shear force, not easy to damage the material structure;

It is submersible, removable, easy to transport, and can be used as a mobile pump;

No rotating parts (or bearings), no mechanical shaft seals, no connectors, low maintenance costs;

The conveying speed can be changed by changing the air volume;

The conveying height can be changed by changing the pressure;

Can transport high-thickness, high-viscosity liquid media;

The outlet can be opened and closed at any time without fear of blockage;

Automatic pressure balance (no pressure relief valve required).

Wilden Pump & Engineering Company of the United States developed the world's first pneumatic diaphragm pump in

Aluminum Air Valve Assembly Fit for Wilden PS4 Pump Wilden diaphragm pump diaphragm technical data:

Optional materials include aluminum, ductile iron, stainless steel and alloy C

Dimensions: 6 mm (1/4") to 51 mm (2")

Wetted part type: BSPT (NPT) or DIN (ANSI)

Elastomers withstand temperatures up to 176.7° C (350° F)

Optional elastomer materials: Wil-Flex?, polyurethane

Maximum outlet/inlet pressure ratio: 26:1

Aluminum Air Valve Assembly Fit for Wilden PS4 Pump Wilden diaphragm pump diaphragm performance data:

Maximum flow: 360 lpm (95 gpm)

Maximum outlet pressure: 20.7 bar (300 psi)

Maximum suction distance: wet suction 9.3m (30.6'), dry suction 7.8m (25.5')

Maximum diameter of solid particles that can pass through: 13mm (1/2")

General advantages of pneumatic diaphragm pumps

Pneumatic diaphragm pumps are the fastest-growing conveying machinery product in recent years. They do not use a motor and use air as the source of power. They can be self-priming and submersible, and can transport high-viscosity and high-viscosity liquid media;

The outlet can be opened and closed at any time without fear of clogging. It is currently the most popular environmentally friendly and energy-saving product on the market.

1. No motor is needed, air is used as the source of power through the air compressor, there is no spark, it can run dry, it can start working by self-priming, no complicated control is required, the operation is simple, and it can self-prime at a height of 6 meters;

2. Liquid media with different characteristics such as strong acid, strong alkali, and strong organic solvent can be transported by selecting the material of the pump shell and diaphragm;

3. No dynamic seal, no pollution to materials, low shear force, not easy to damage the material structure;

4. It is submersible, movable, easy to transport, and can be used as a mobile pump;

5. No rotating parts, no mechanical bearings, no connectors, low maintenance costs;

6. The conveying speed can be changed by changing the air volume;

7. The conveying head can be changed by changing the pressure;

8. It can transport high-thickness and high-viscosity liquid media;

9. The outlet can be opened and closed at any time without fear of blockage;

10. Automatic pressure balance (no pressure relief valve required)